Overview

Innovation of Filtration

For over a century, Donaldson has been a leader in filtration technology, manufacturing, and testing. In tightly regulated markets, our research and development efforts have produced more efficient, longer-lasting filtration systems and filters. We offer in-house engineering expertise and are continuously investing in research and development to improve system designs and filtration technologies. As equipment and technology advance, we continue to develop innovative solutions to anticipate and exceed evolving engine and equipment requirements.

We’re also fully committed to delivering quality products and being a responsible corporate citizen. You’ll find that Donaldson strives to meet or exceed customer requirements, and we do so by coordinating a wide range of continuous improvement activities.

OEM Support Needs

Problem Investigation, Predictive Simulation, Concept Verification, and Production Validation.

When developing new equipment platforms, OEMs need the assurance that potential suppliers are capable of meeting the performance requirements for a given application. This often includes solving known issues from past applications – or meeting an all-new spec that's intended to address a new performance challenge.

OEMs need supplier partners that have the expertise and capability – and the tools at their disposal – to investigate problems, predict outcomes, and evaluate and prove that you have the best solution to meet a particular challenge. And once solutions move to production, these partners also need to verify that production parts can be reliably and repeatably manufactured.

Effectively deploying the right capability at the right time in the development cycle mitigates unanticipated expense later – and proposed solutions need to be delivered in a timely and cost-effective manner.

Investigation

Problem Investigation

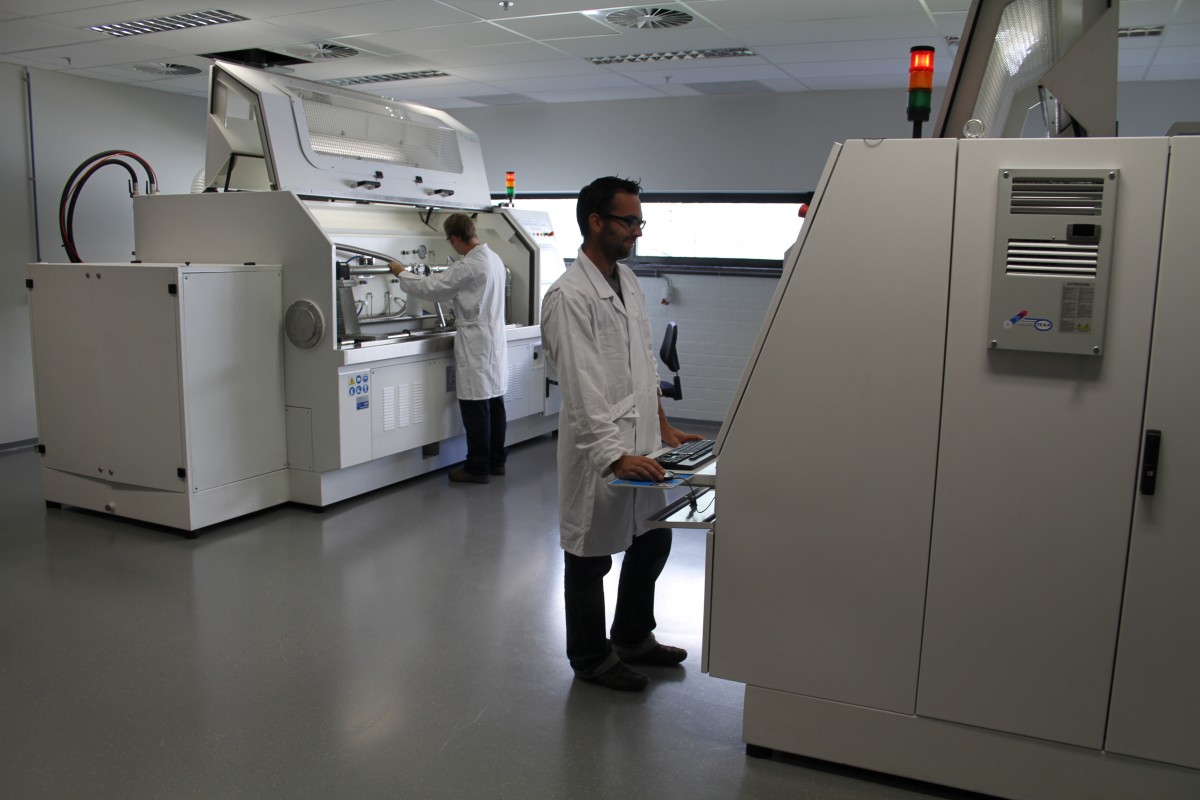

This is the point at which most new projects begin – with a new application that includes unique requirements or an unsolved problem. Our global team of engineers, scientists, and field service resources are available to help identify and address these challenges. They have a range of tools, including full-service global labs, at their disposal.

Competencies

Extensive experience in investigation, analysis, and solutioning:

- Application requirements review

- Root cause and problem-solving methods

- Fluid and contaminant analysis (chemistry lab)

- Used filter analysis

- Solution ideation

Capabilities

A full-service Analytical Chemistry Laboratory with the following:

- Optical microscopy

- Scanning Electron Microscopy (SEM)

- Fourier Transform Infrared (FTIR)

- Thermal analysis, including Differential Scanning Calorimetry (DSC) and Thermal Gravimetric Analysis (TGA)

- Laser diffraction particle sizing

- Dynamic Mechanical Analysis (DMA)

- Gas Chromatography-Mass Spectrometry (GC-MS)

- Liquid Chromatography-Mass Spectrometry (LC-MS)

Simulation

Predictive Simulation

We have the capability to predict the performance and outcomes of a potential solution, before making significant time and resource investment in design and prototyping. We can employ this process to look at a wide range of potential solutions, distilling thousands of ideas down to the one or two that provide the optimal result.

Competencies

Strong physics-based modeling and simulation technology and data science:

- Computational fluid mechanics

- Structural analysis

- Material characterization and contaminant characterization

- Particle tracking and particle simulation

- Multiphase fluids and flows

- Chemical modeling

- Thermodynamics

- Machine learning

- On-premise and cloud high-performance computation platform

Capabilities

Offering a range of Donaldson-developed proprietary modeling and simulation capabilities:

- Filter media and membrane performance prediction

- Filter element (flute / pleat) performance prediction

- Inertial separator performance

- Performance prediction in system level

- Parts / housing / air cleaner fatigue, vibration, and life prediction

- Nonlinear material behavior prediction (for example: seal)

- Modeling of filter manufacturing process

- Plastics injection modeling process and plastics part quality

- Chemical absorption and adsorption

- Remaining filter life predictions communicated to real-world applications in real-time

Verification

Concept Verification

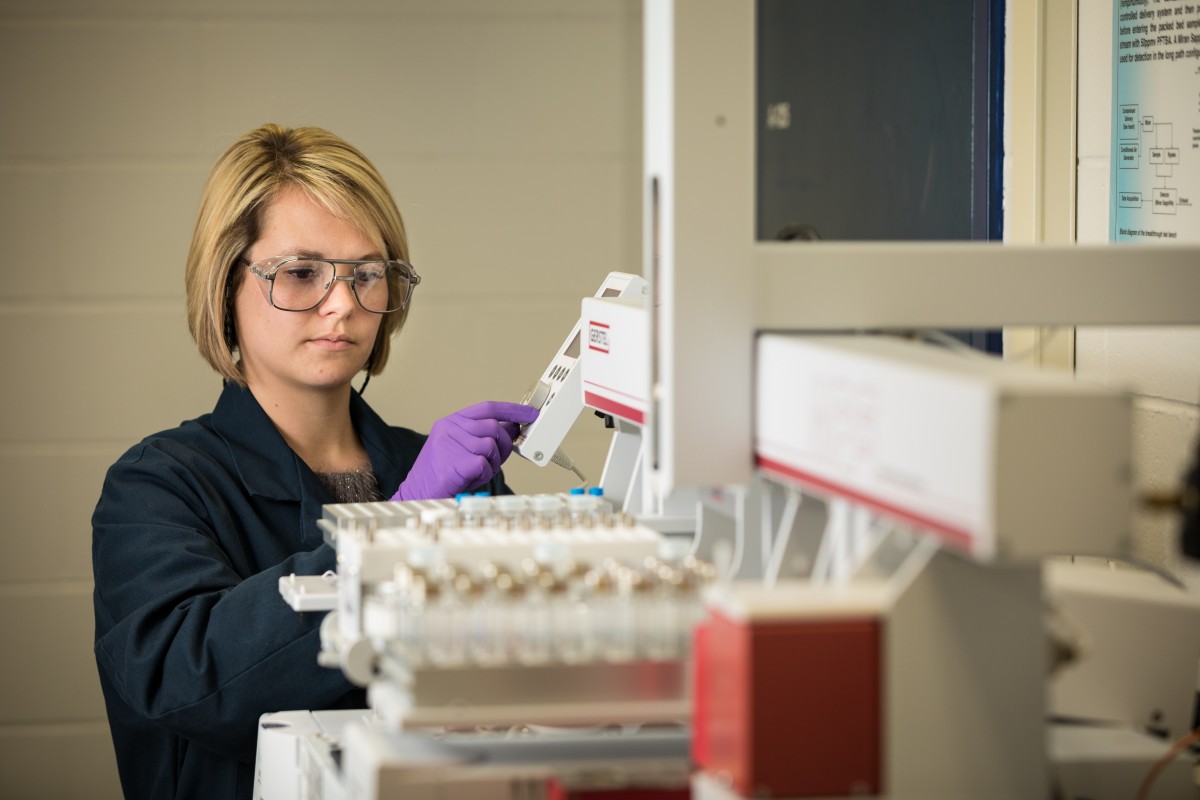

Our extensive prototyping capabilities allow us to quickly move from the virtual solution (model) to the development of a physical part. We create these prototypes to allow us to verify the simulated results. This critical step in the development process allows us to build confidence in the proposed solution and reduces risk as we move into production.

Competencies

A full-service rapid prototyping laboratory, including the following:

- 3D design services

- 3D printing and various additive manufacturing resources

- Reductive Computer Numerical Control (CNC) machining

- Investment casting

- Room Temperature Vulcanization (RTV) molding

- Media forming and pleating

- Element assembly and potting

Capabilities

A full-service flat-sheet media laboratory to measure and verify:

- Efficiency

- Capacity

- Differential pressure

- Tensile strength

- Burst pressure

- Bubble point or pore size analysis

- Permeability

- Thickness and height

Material property testing:

- Stress / strain / fatigue life of proprietary materials, components and assembly properties

Validation

Production Validation

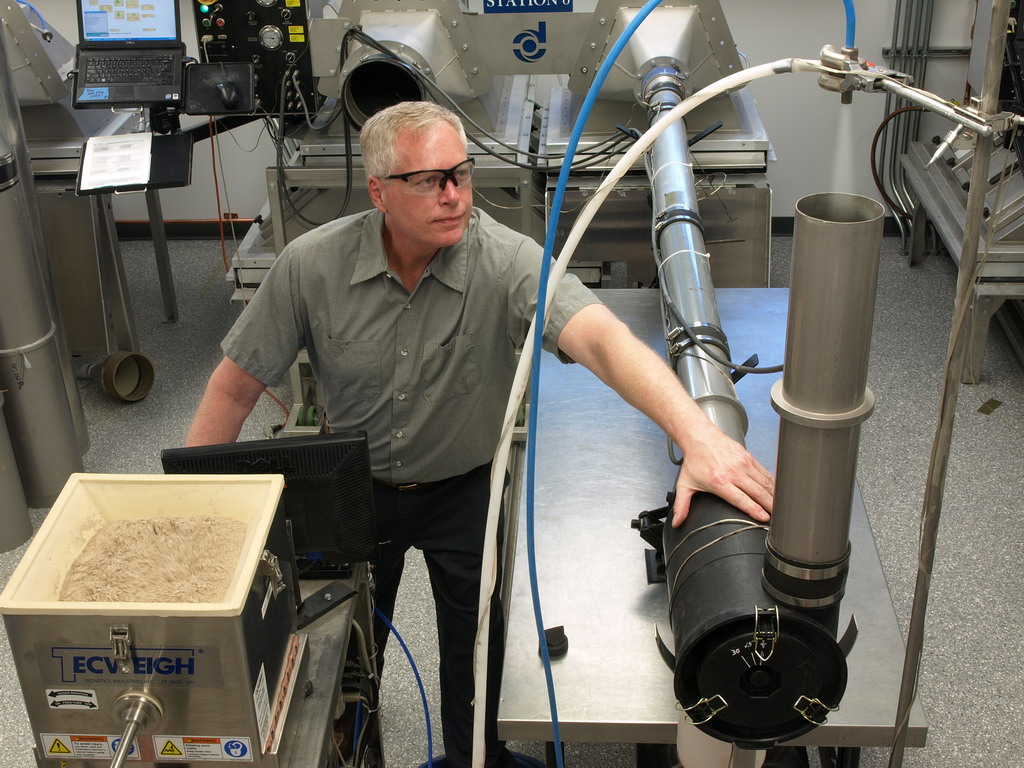

After making a significant investment in production materials and processes, we need to validate that everything we've done up to that point yields the intended result. Performance and integrity testing validates that initial production parts are able to meet the expected performance and life requirements. Once launched into production, we repeat key tests that validate the quality assurance of our manufacturing processes over time.

Capabilities

Filter and assembly performance testing conforming to:

- International Organization for Standardization (ISO), Society of Automotive Engineers (SAE), National Fluid Power Association (NFPA) standards

- Real-world vehicle applications and environments

- Customer standards and specifications

A suite of full-service test laboratories to measure and validate:

Filter and assembly performance under steady-state or dynamic test conditions:

- Efficiency of contaminant removal (particles, water, air, or other organic materials from a variety of fluids)

- Gravimetric or fractional measurement and analysis

- Filter life as measured by contaminant capacity

- Differential pressure over the life of the filter

Filter and Assembly Durability:

- Accelerated life testing

- Random vibration / Power Spectral Density (PSD) and shock

- Resonance search and dwell

- Leak inspection

- Dynamic environmental conditions

- Thermal cycling

- Hydrostatic burst and collapse

- Pressure fatigue, pressure impulse and fabrication integrity

- Flow fatigue and filter media integrity

Donaldson test laboratories monitor and precision control test conditions for either steady-state or dynamic filter inputs including:

- Vibration and acceleration

- Cyclic fluid flow

- Pressure pulsations

- Multiple contaminant types

- Internal and external environmental replication including temperature, relative humidity, and salt spray