Overview

Our alternative power filtration solutions are designed to reduce dependence on fossil fuels, lower greenhouse gas emissions, and enable greener operations, all while maintaining top-tier productivity levels.

Experience. Expertise. Performance.

For more than 20 years, Donaldson engineers and advanced materials experts have worked collaboratively with leading OEMs and Tier 1 / Tier 2 suppliers to develop customized solutions that meet specific fuel-cell application requirements in critical areas.

Products

Donaldson offers customized solutions that incorporate high efficiency media and carbon layers to effectively address the sources of fuel cell contamination.

H₂ Gas Filtration

Hydrogen fuel can be contaminated with oil, water, gases, and sulfur compounds. To ensure the fuel cell is protected, it's crucial to have a filter installed on a vehicle.

To address this, Donaldson can provide a high-pressure fuel filter (up to 420 bar) and a low-pressure filter (below 25bar).

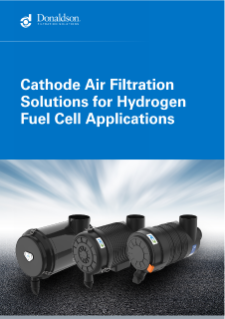

Cathode Air Filtration

A fuel cell requires air to function, and the purity of this air can greatly impact the performance and lifespan of the fuel cell. Typical filter media for fuel cell cathode air consists of multiple layers, including activated carbon, an acid and base layer, and a dust filter layer.

Donaldson has over a century of experience providing innovative solutions for dusty environments and has applied this expertise to its fuel cell cathode filter products.

We can offer:

- Dedicated element

- Fully customized

- Catalog products

- Chemical filtration only

Water Separator

Liquid water can pose a challenge for fuel cells in several areas:

- The intake air filter should stay as dry as possible, so any type of water needs to be removed before the air reached the intake air filter.

- The fuel cell can be boosted by a turbo charger in high performance applications. In this scenario, there is a high-speed turbine in the exhaust which must be protected from liquid droplets.

- There are applications where it is necessary to control the discharge of liquid water, out of the tailpipe.

ePTFE Reinforcement Membrane

Proton exchange membrane fuel cells rely on Perfluorosulfonic Acid (PFSA) ionomer, which swells when exposed to high humidity and contracts when moisture levels are low. This swelling and contracting can cause mechanical stress and eventual failure in the ionomer, making reinforcement necessary for high-performance PEM system.

Expanded PTFE is an ideal material for reinforcing the ionomer due to its mechanical strength, chemical resistance, and high porosity. The ePTFE skeleton plays a critical role in ensuring micro-scale mechanical durability and is an essential component in the design of fuel cell stacks.

Fuel Cell & Battery Vent

The fuel cell stack is enclosed in a housing with ingression protection, which must be sealed to protect the fuel cell. To achieve this, a membrane vent is utilized, which enables the enclosure to breathe while preventing dirt and moisture from entering the fuel cell surroundings.

Donaldson's Tetratex® membrane offers a durable and breathable solution for fuel cell housing. It can be integrated directly into the housing to create vent assemblies that meet specific application requirements, providing both protection and ventilation for the fuel cell stacks.

Humidifer

The humidity of the fuel cell membrane is a vital factor in maintaining the optimal operating conditions of the ionomer in the fuel cell. Fuel cells require a high and stable level of humidity in the air supply to function efficiently.

The humidifier is responsible for transferring humidity from the exhaust gas to the inlet air stream before it enters the fuel cell, ensuring that the fuel cell has the correct level of humidity to operate at its best.

Coolant Ion Exchanger

The coolant used in a proton exchange membrane (PEM) fuel cell plays a vital role in regulating the fuel cell's temperature and removing waste heat. To ensure optimal performance, it is necessary that the coolant has a low dielectric constant and remains non-conductive.

Over time, ions from the materials used in the bipolar plates, radiators, and all coolant circuit components can migrate into the coolant and increase the electric conductivity. To counteract this, the coolant is passed over an ion exchange resin which captures said ions, therefore ensuring the coolant remains electrically non-conductive.

Additionally, to prevent large particles from blocking the channels in the bi-polar plates, a screen is integrated into the same housing.

Applications

Innovation For the Right Application

Buses

Hydrogen fuel cell buses powered with Donaldson technology transport people all around the world. We are helping to reduce carbon footprint and eliminate local pollution.

On-Road Trucks

Our solutions provide filtration and innovative technologies to help trucks ranging from heavy-duty to light-duty achieve zero emission.

Off-Road Equipment

As a leader of filtration technologies in the field of off highway equipment, we are investing our competencies to next generation’s equipment for a sustainable tomorrow.

Videos

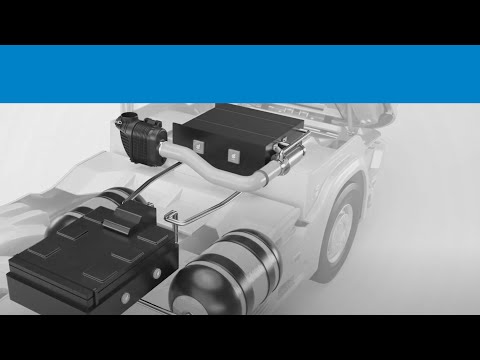

Donaldson Alternative Power

Donaldson is shaping the future where alternative power and efficiency coexist harmoniously.

Donaldson Fuel Cell Solutions

Donaldson offers experience and capabilities for suppliers and manufacturers of Hydrogen Fuel Cells - including air intake filtration, membrane technology, and fuel cell and battery vents.

Resources