Combination of Causes

Maintaining dry fuel has become more important – and more challenging – in recent years due to an untimely convergence of factors:

- Ultra-low-sulfer diesel (ULSD) requires additives to meet lubricity specifications which make it harder to remove water from the fuel

- Many states require increased use of biodiesel blends which can hold up to 10-25x more water than traditional diesel fuel

- The injectors in today’s complex high-pressure common-rail systems (HPCR) are more susceptible to premature wear and damage from water

Water has been shown to cause up to 30% of HPCR system failures. And when combined with the variability of fuel sources and the high levels of ambient water diesel fuel is regularly exposed to, it has quickly become a major problem for equipment manufacturers, owners, and fleet managers.

Countering with Coalescing

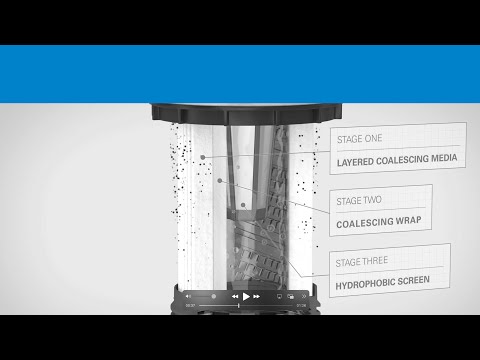

To help address these challenges, Donaldson created Synteq™ DRY, an advanced, multi-stage coalescing technology that delivers industry-leading fuel water separation for greater protection.

Specifically designed to work with today’s ULSD and biodiesel blends, Synteq DRY:

- Removes 80-90% more water from fuel over the life of the filter – significantly more than standard filters and other coalescing filters in the market

- Is highly resistant to degradation from contaminants even when fouled

- Retains its performance and efficiency throughout the life of the filter — even in the most challenging operating conditions

Fuel Fact:

A dry bowl doesn't always mean dry fuel. If there's no water in your bowl, you can likely find it in your fuel system.

With a typical injector repair costing around US $1,200 and a pump repair around US $2,200, industry-leading water removal efficiency is a sound investment. Drier fuel can help extend the life of your equipment, keep your operation running, and save you money.

Winning the War Against Water in Fuel

Water in fuel causes nearly 30% of all HPCR system failures. In the last five years, fleet managers spent more than $3B on pump and injector repairs related to excessive water in fuel systems. Even when fuel comes from dry sources, condensation can continually add water to the fuel after it’s in the tank. What is water costing you?