Overview

Manufacturing bottled water requires the filtration of compressed air, liquid and steam. Donaldson’s full suite of process filtration technologies ensures that the final product meets global food safety standards.

We have extensive experience applying our compressed air filtration solutions to the bottle blowing process for some of the largest global bottled water manufacturers. Our high pressure compressed air solutions ensure the air used to blow open and shape the PET bottles is free of particulate, moisture, oil vapor, and bacteria.

Our liquid product portfolio is geared towards preparing spring, well or mineral water for bottling. Our liquid process housings offer sanitary designs that eliminate harbor points for bacteria and our LifeTec elements can do everything from protecting fragile RO membranes from particulate to removing micro-organisms from the final product.

Our steam filtration solutions are critical to following industry best practices and maintaining process integrity. By sterilizing the air and liquid elements that are capturing bacteria, the end user ensures the microorganism are not allowed to propagate and contaminate the final product. Our stainless steel housings and elements are designed to handle the harsh environment of steam systems and produce clean steam at various points of use.

When Donaldson’s Process Filtration product portfolio is used in conjunction with industry best practices, we can effectively protect the brand and product integrity for bottled water manufacturers.

Products

Applications

- Bulk Water Filtration

The removal of large contaminants from source water provides protection for the boiler and pre-filtration for finer filtration solutions.

- Sterile Liquid Filtration

The removal of micro-organisms prior to the packaging of bottled water.

- Compressed Air Purification

Bulk water and particulate removal from compressed air providing protection for pneumatic tools and equipment.

- Sterile Air Filtration

The removal of micro-organisms from compressed air used for bottle blowing.

- Tank Venting

The removal of micro-organisms from make-up air on product storage tanks.

- Culinary Grade Steam

The purification of steam used for sterilization of process equipment.

Regulatory

Filtration for Purity in Bottled Water Processing

While facilities vary, in general, filtration as part of the preventive control is recommended at the following stages of bottled water processing:

- Incoming source water: Pre-filtration of well water to remove sediment, particulates and larger microorganisms through a 25 micron filter; produces factory water suitable for equipment and container cleaning.

- Intermediate processing: Depth filtration through a 5 micron filter to remove smaller particulates and impurities shed during resin or carbon activation steps to gain particulate-controlled water – usually used for dilution of CIP reagents.

- Fine filtration: Filtration through a 1 micron filter to remove colloidal contaminates like humic acids potentially present in the water or in containers.

- Final filtration: Critical filtering through a 0.2 micron filter just prior to packaging, using a highly efficent membrane filter to capture last remaining contaminants.

- In storage: Tank vent filters on stored product in holding tanks, to prevent the ingression of airborne contaminants while equalizing tank pressure as volume changes.

Working with an experienced filtration partner can help you design a system that is both compliant and cost-effective.

These complimentary resources from Donaldson provide a head start:

Regulatory and Best Practice Overview

A summary of applicable filtration and sanitary design standards for liquids,

steam, and sterile air use in food and beverage processing.

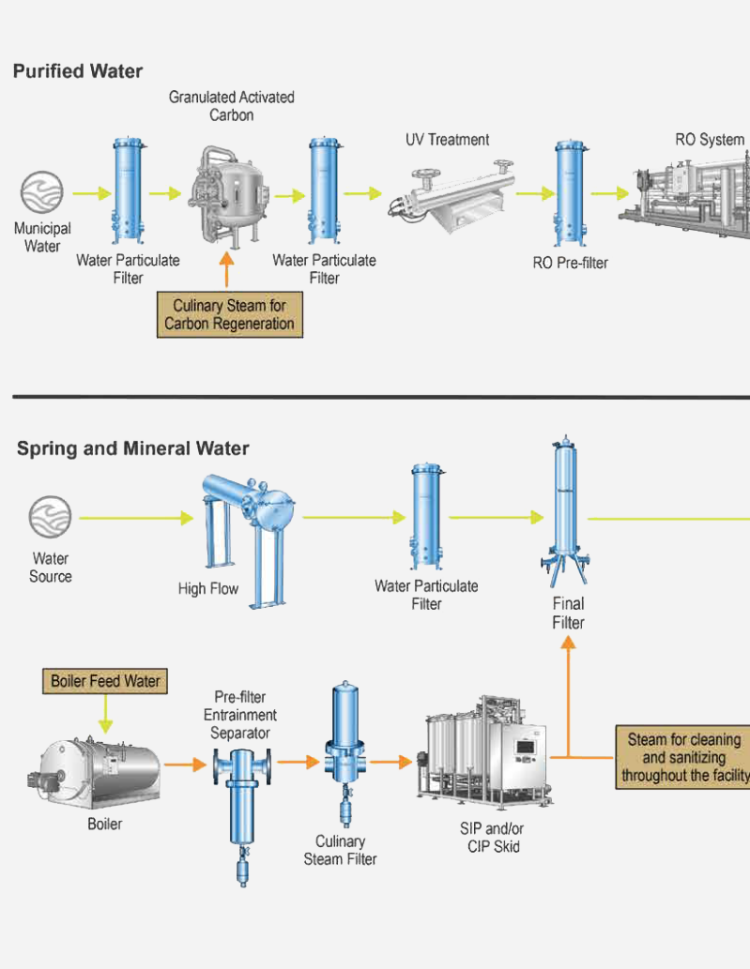

Filtration Map for Bottled Water

A diagram illustrating common control points in bottled water

processing, along with filtration solutions to consider at each point.

Filter Maintenance Schedule

A recommended filter replacement schedule for steam, compressed air, and

liquid filters in a process line, to optimize both safety and cost efficiency.

Videos

Articles