-

Products

- Overview

- Compressed Air & Gas

- Compressed Air & Gas (cont)

- Liquids

- Filtration Systems

- Steam

- Competitive Fit Filters

- Filter Test Equipment

-

Compressed Air & Gas

-

path: /content/donaldson/en-be/compressed-air-process/products/compressed-air-gas/aftercoolersAftercoolers

-

path: /content/donaldson/en-be/compressed-air-process/products/compressed-air-gas/breathing-air-systemsBreathing Air Systems

-

path: /content/donaldson/en-be/compressed-air-process/products/compressed-air-gas/condensate-management-systemsCondensate Management Systems

-

path: /content/donaldson/en-be/compressed-air-process/products/compressed-air-gas/dryersDryers

-

- Industries

- Resources

-

Technology

-

Service

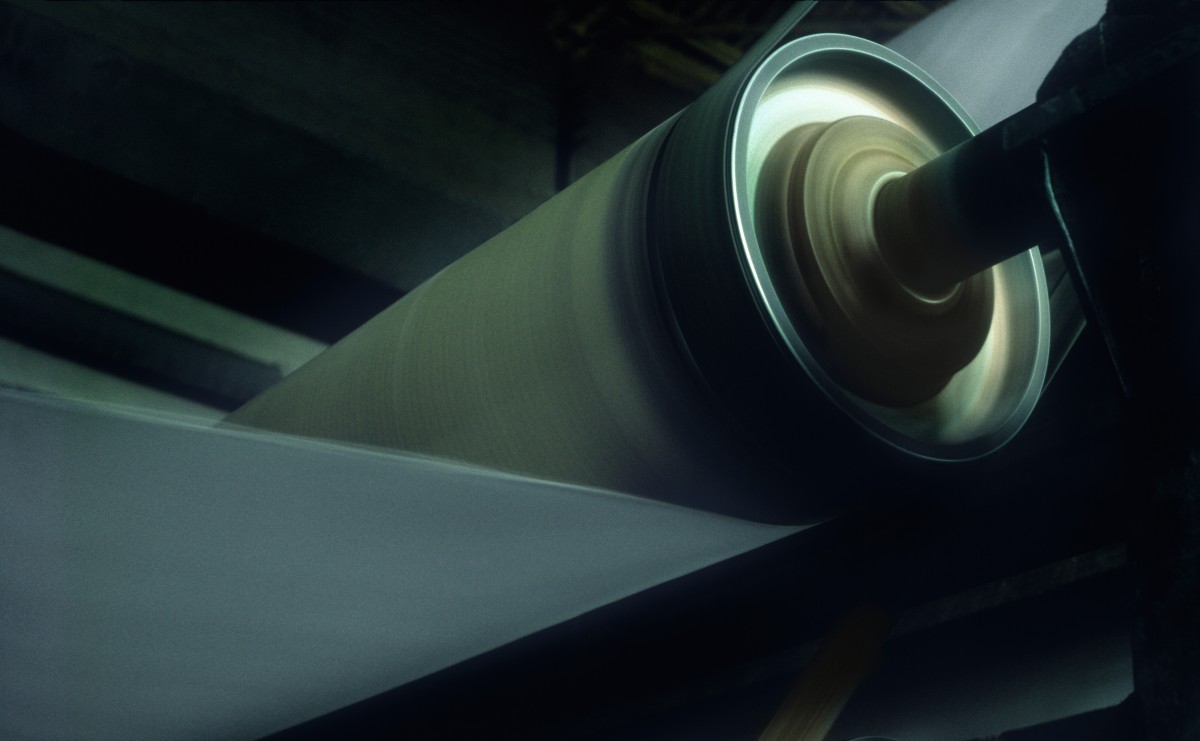

Pulp & Paper

High-Performing Products for Demanding Applications

Overview

A recognized leader in quality replacement filters, Donaldson steam, compressed air and liquid filtration products are engineered to fit a wide range of applications used in pulp and paper mills.

Pulp and paper mills require the assurance of high performing products for demanding applications.

Products

Compressed Air & Gas

Your selection did not return any results. Please reset and try a new selection.

Condensate Management Systems

We offer complete product lines in oil water separators and drains for reliable and economical disposal of compressed air condensate.

Filter Housings

Donaldson's high quality compressed air filter housings are used to purify air and technical gases for both industrious and process housing.

Filter Elements

We offer industrial filter elements for any industrial application in the extensive Donaldson line.

Liquids

Your selection did not return any results. Please reset and try a new selection.

Filter Housings

Donaldson offers reliable, high quality housings for purification and sterile filtration of liquids process industries.

Filter Elements

Donaldson offers filter elements to protect the integrity of your liquids and utilizes cartridge filter elements to enhance product performance. Our premium LifeTec™ filters offer increased reliability and lower operating costs.

Steam

Your selection did not return any results. Please reset and try a new selection.

Filter Housings

Donaldson's filter housing line includes high-quality stainless steel filters for the purification of industrial steam in different applications and flow rates.

Filter Elements

Donaldson's line of filter elements features a reliable steam filtration for every application in order to protect equipment and industrial or other processes. Our premium LifeTec™ filters offer increased reliability and lower operating costs.

Applications

- Boiler steam filtration

- Protection of process piping and equipment from steam contaminates

- General compressed air applications

Articles

Close