By Scott Grimes, Donaldson Process Filtration

Brewers, welcome to the world of regulation. Under the Food Safety and Modernization Act (FSMA) of 2011, beer and other alcoholic beverages are now a regulated food. Whether you’re a large-scale brand or a microbrewery, FSMA requires that you identify all potential contamination sources in your facility and take intentional steps to prevent foodborne illnesses.

This due-diligence process is called developing a Hazard Analysis and Critical Control Points (HACCP) plan. According to the letter of the law, the FDA can inspect and fine breweries that don’t have an acceptable HACCP plan.

Regulations aren’t the only reason to develop a HACCP plan, however. The new requirement is an opportunity to protect the quality of your product and ultimately your brand reputation. Examining your facility through a food safety lens can spur improvements that will help maintain consistent beer flavors and achieve the stable shelf life you need to expand distribution.

Brewery Contamination Risks: An Overview

Although the alcohol content of higher ABV beers tends to be a natural purifier, there is no ABV level recognized as completely safe. Food safety hazards in brewing are comparable to many other kinds of food production.

Potential biological contaminants are present in the cereal grains, flavoring, or process aids you use. But overlooked risks are the water, steam, and gas used in the process itself. These process “utilities” can carry in dirt, oil, and bacteria from the outside world or pick them up inside system piping. Hard particulates can damage equipment downstream, and even small microbe deposits can multiply into larger colonies.

Cleaning and sanitation practices do not stop all common invaders. So, while you’re familiar with the product filtration step that clarifies your brew after fermentation, additional process filters are important throughout your facility.

Filtration on “Critical Control Points”

The brewing industry has yet to develop consensus standards on exactly where and how to filter utilities within the brewing process. Until then, guidelines for general food processing apply, namely 3-A Sanitary Standards and Safe Quality Foods (SQF) standards. These design standards are the backbone of a HACCP plan for other beverage industries.

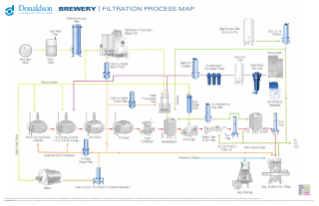

Process filtration is recommended in three regions of your plant:

- Prefiltration: In utility rooms or bulk storage areas where water, steam, and air sources are first brought in or generated;

- Intermediate filtration: At process steps where water, steam, and air travel through piping or equipment before making direct contact with product or process surfaces; and

- Final filtration: Near the end of processing, where there’s a final opportunity to address surviving contaminants before they damage a finished beverage.

Every brewery is unique and yours may have additional filtration needs, but below are the control points where filtration is typically recommended:

1) Before Malting, Mashing, and Boiling

Contamination risk: Water

Precaution: Pre-filter at the source and sterile-grade filter at point of use

The brewing process begins with large volumes of water. Water germinates the milled barley into malt. More water is added with cereal adjuncts to create a mash. The mash and hops are cooked with a steam boiler fed by water. Hot rinse water is used throughout lautering. And of course, water cleans process equipment.

The importance of filtering source water can’t be overstated. Although the boil is an effective kill step, dirt, rust, and scale can be present in water, especially if it’s drawn from a well or river. Use a pre-filter of 10 microns on the water line entering your process to capture 95% to 98% of foreign sediment and other contaminants. Well or river water carrying a greater amount of debris may require a series of 50-, 20- and 10-micron pre-filters. Prefiltration helps protect downstream equipment from clogging and corrosion and lightens the load on any finer filters downstream.

Once the boil process is complete, any additional procedure or ingredient introduces a contamination risk. If water is used to wash containers, for example, sterile-grade water should be used.

What is the difference between sterile and non-sterile filtration?

A sterile filter is required wherever there is direct contact with a product or its surfaces. Sterile filters are used to remove kettle finings, for example, or purify compressed air used to ionize cans before filling.

For liquid, air or gas to be considered sterile by FDA standards, it must be filtered to a Log Reduction Value of >7. That is, the number of germs must be reduced by 107. To achieve this, a .2-micron filter media is most ideal. It should be “absolute rated”—designed with that exact, consistent pore size.

Larger-micron, “nominally rated” filters are acceptable for non-sterile applications, such as pre-filtering steam boiler feed water. Not all filter suppliers test their elements for capture efficiency. Choose filters that have been tested to perform the intended job.

2) Between Lautering and Fermenting

Contamination risk: Gas or sterile air

Precaution: Prefilter at the source and sterile-grade filter at point of use

After the Lautering process separates spent grains from the clear wort in the brew kettle, the wort is ready for conversion into beer. Before fermenting yeast is added, the wort needs aeration to help the desirable organisms propagate and break down the product into simple sugars.

Compressed air or oxygen is used for aeration, and they both pose another risk. Compressor equipment and tanks can leak oil, moisture and microbes. To protect this critical step, a pre-filter is recommended on air, nitrogen, CO2 and oxygen lines in the utility room. Further, a sterile-grade filter rated at 0.2 microns (with a Log Reduction Value of >7) should be placed at point of use on the wort aerator.

Larger facilities use a yeast propagator, which can also use sterile air or oxygen. In addition, this equipment needs cleaning between batches, requiring culinary-grade steam. This is steam filtered to remove 95% of suspended solids 2 microns or larger in diameter.

3) Post-Fermentation in Tanks

Contamination risk: CO2

Precaution: Tank blanket and sterile air vent

Once the yeast in fermenting vessels has been crashed (chilled to halt fermentation), tank pressure can fluctuate during emptying and filling, posing a risk of tank collapse. Because the tank is no longer producing its own CO2 for counter-pressure, a good solution is injecting a CO2 “blanket” into the tank and placing a sterile air tank vent at the top of the vessel. The vent allows air to flow in and out, compensating for changes in volume, while inside the housing a sterile-grade hydrophobic filter element to screen out particulates and bacteria from inflowing air.

CO2 is also used for product push—transferring the brew from one tank to the next. Any CO2 that touches the product should be sterile-filtered.

4) After Kettle Finings

Contamination risk: Biological substance

Precaution: Absolute-rated liquid filter

Before clear beer glasses became popular, hazy brews were acceptable to consumers. Today, clarifying the beer is an essential step to achieve the desired color on the 2 to 40+ Standard Reference Manual (SRM) scale. Isinglass, a collagen derived from fish, is a commonly used clarifying agent, sometimes called “kettle finings.” Other substances used include polyphenols, beta glucan, oxalates, and carrageenan.

Once these fining compounds have done the job of isolating and settling yeast and beer proteins, they need to be filtered out. For this, an absolute-rated polypropylene liquid filter element is recommended, such as a Donaldson LifeTec™ Filter. This filter was developed in collaboration with some of the world’s leading beer brands. The micron value of this liquid filter depends on the type of beer you are brewing.

5) During Final Product Filtration

Contamination risk: Bulk processes

Precaution: Additional liquid or gas filters

After removal of kettle fines, most breweries send their product through one final bulk filtration. (Others combine the previous clarifying step and final filtration into one procedure.) There are several methods for this final removal of remaining impurities: plate-and-frame, centrifuge, and diatomaceous earth. Each one may require additional filtration, depending on your conditions and desired product.

Diatomaceous Earth (DE) is the most traditional bulk filtration practice and is lowest in cost. Two membrane filters will help DE systems perform optimally: a trap filter to remove any yeast or perlite particles that might have made their way downstream; and, if CO2 is used to drive off oxygen during the dose feed stage, a gas filter on the CO2 as a precaution against contaminants.

Plate-and-frame filtering often uses CO2 to push large volumes of beer through the equipment. A sterile filter should be placed on this gas just before it contacts the product.

Centrifuges are coming into favor for their comparatively low operating expense. If your goal is greater beer clarity, another liquid filter of 5 microns can be added downstream of the centrifuge. If you do so, structural integrity is important. If you operate a high-volume facility, choose a filter (such as LifeTec™ PP100 N Filter) designed to maintain high flow rates, resist collapse, and be regenerated, which all help to maximize filter life.

6) In Conditioning, Kegging and Bottling

Contamination risks: Compressed air, gas and water

Precaution: Sterile-grade filtration

After final product filtration, there are a number of locations where conditioning, bottling and kegging can introduce contamination risks. Here are recommended precautions:

Conditioning: For lager products that are conditioned in a refrigerated vessel, CO2 is recommended to counter-balance tank pressure, and a sterile-air tank vent should protect the tank contents (just as in the post-fermentation step). The gas can carry contaminating production byproducts and should be filtered with activated carbon.

Keg washing: Use a pre-filter to remove sediment from water used to chemically clean kegs in a clean-in-place (CIP) process. When you rinse and steam the kegs, make sure it is filtered to culinary-grade (removing 95% of particles 2 microns and larger). If you use a compressed air purge to dry the kegs, it should be sterile-air filtered. Finally, if you charge the inside of the keg with CO2 to displace oxygen, filter the CO2 first.

Can cleaning: Before filling, cans are frequently dry-washed with an ionizer to remove dust and sediment. This device uses compressed air, which should be treated first with a sterile-grade air filter, such as the Donaldson P-SRF. If a water rinse is used instead, a 1-micron liquid filter is recommended at this point of use.

Bottle filling: Many brewers use a foam-over bottling process (FOB) to remove oxygen before capping. A micro-pulse of water is applied to the beer surface, causing it to foam and displace oxygen. Since the water is in direct contact with finished product, it should be sterile-filtered.

Conclusion

A significant contamination source in beverage processing can be the water, steam, air, or gas used in the process itself. Properly staged filtering can help reduce this risk. Breweries that use multiple ingredients, heat and air treatments, and packaging steps may require a more complex filtration system. But every plant has a common challenge: control incoming contaminants and critical control points. As a rule of thumb, these are:

- Points where contamination is first generated or introduced; and

- Points where product contamination is at highest risk or where there’s a “last chance” to remove it.

What you’re aiming for in pre-filtering, intermediate filtering, and final product filtering is redundancy. When a process involves costly ingredients as well as your reputation, filtering “early and often” throughout the process is a good policy.

Finally, work with a trustworthy filtration partner who can help you evaluate your needs and recommend appropriate product options. Make sure they’re qualified to help select the most cost-effective elements and verify the performance of their filters.