Overview

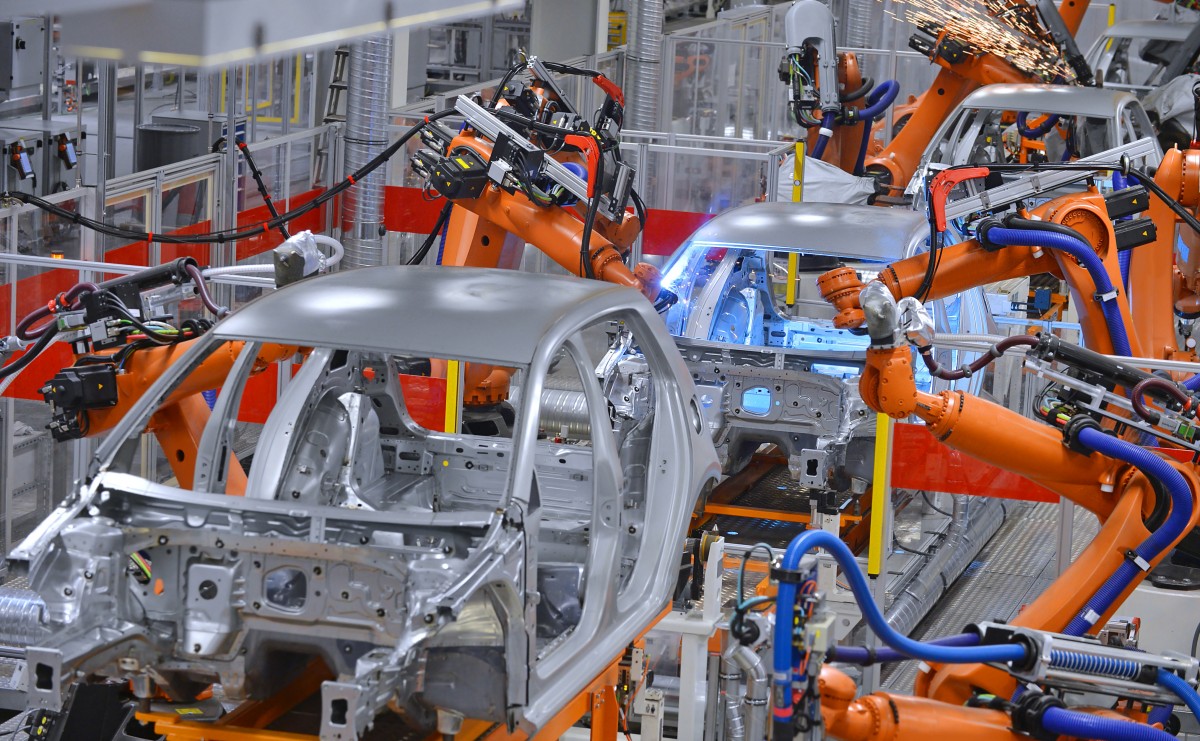

Compressed air is an integral part in running the high precision equipment used to build and paint thousands of new vehicles everyday. Downtime due to maintenance can be very costly which is why it is important that compressed air, water and steam utilities are properly filtered from harmful contaminants that will quickly degrade the life of manufacturing equipment and reduce product quality.

Donaldson's solutions on compressed air and process filtration have been designed for excellence, promising maximum performance and minimum maintenance downtime.

Products

Compressed Air & Gas

Liquids

Steam

Applications

- Pneumatics

- Paint

- Cooling

- Part cleaning

Articles

Close