Overview

Donaldson products are used throughout the pet food manufacturing process. Our liquid, steam, and sterile air solutions help manufacturers across the globe reduce the risk of contamination and meet regulatory requirements - from the beginning of the process through the packaging of the product.

Water used to feed Clean-In-Place (CIP) and Steam-In-Place (SIP) systems, and supply boilers for steam typically comes from municipal or well sources. These sources have contaminants that will reduce the life and reliability of process systems. Our liquid housings and elements will purify incoming water and prolong the system’s useful life by removing particulates. Water can also be used as a mist to deliver a uniform vitamin coating on dry food pellets. Filtered water improves the pet food quality and reduces the risk of contamination.

Products

Applications

- Filter water up to ingredient water

- Culinary steam used to cook food and sterilize cans supports proper shelf life and product consistency

- Removing impurities from compressed air used to dry equipment after nightly wash-down reduces risk of contamination and complies with best practices

Regulatory

Filtration Requirements in Pet Food Processing

Food safety regulations extend beyond human consumables to most pet food processors, as well. Facilities that produce pet food are subject to the U.S. Food Safety Modernization Act (FSMA) of 2010, as well as a number of industry standards, such as Safe Quality Foods.

You are required to have a comprehensive Hazard Analysis and Critical Control Points (HACCP) or Hazard Analysis and Risk-based Preventive Controls (HARPC) plan in place, including proper filtration of the air, water, and steam used in your process.

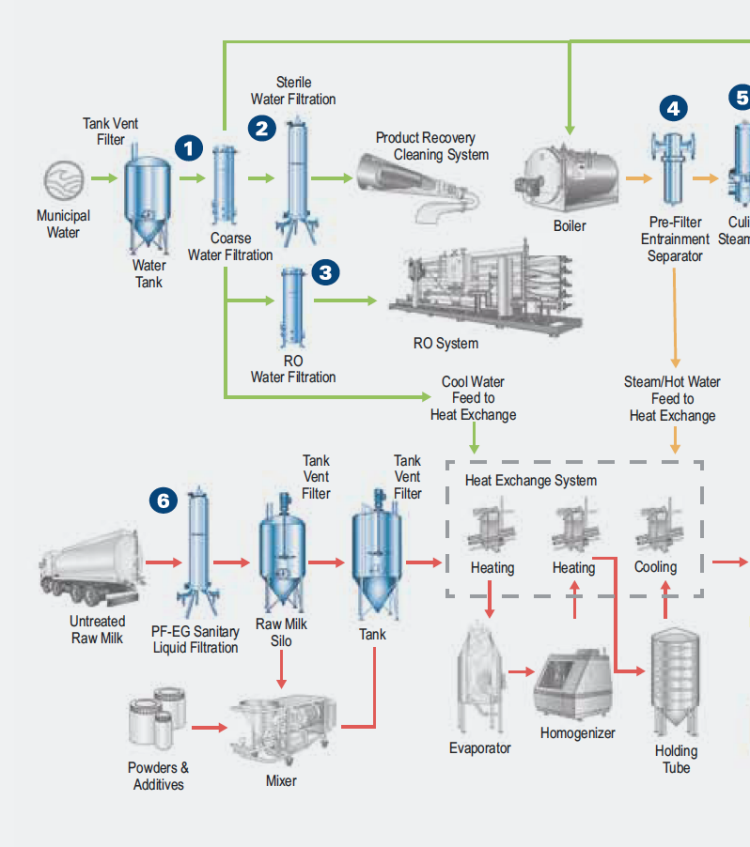

Each pet food facility will have unique needs, but in general, there are at least 13 locations where filtration is critical to the safety of your product and equipment. Here are just some examples:

- Source water: Municipal or spring water used to feed boilers or clean-in-place (CIP) and steam-in-place (SIP) systems.

- Ingredient water: Process water used to adjust moisture content during product blending.

- Culinary-grade steam: Steam used to condition meat, or cook product in cans at specified temperatures.

- Extrusion: High-pressure steam that forms food into its final shape and size.

- Compressed air: Air used to dry equipment after it's washed.

Working with an experienced filtration company will help you develop filtration that is both compliant and cost-effective.

We offer these complimentary resources as a starting point:

Regulatory and Best Practice Overview:

A summary of applicable filtration and sanitary design standards for liquids,

steam, and sterile air use in food and beverage processing.

Filtration Map for Pet Food Processing:

A diagram illustrating common control points in pet food processing facilities,

along with filtration solutions to consider at each point.

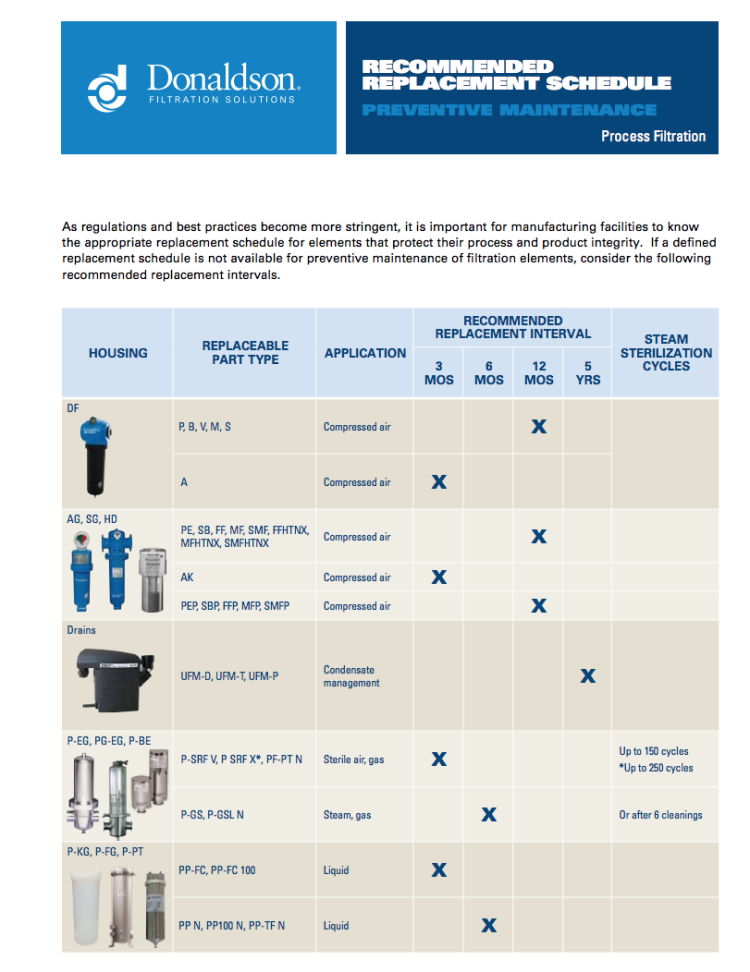

Filter Maintenance Schedule:

A recommended filter replacement schedule for steam, compressed air, and

liquid filters in a process line, to optimize both safety and cost efficiency.

Resources

Articles