Overview

Donaldson Torit® dust collectors are in hundreds of thermal spray applications worldwide.

Our advanced Ultra-Web® fine fiber filtration technology is supremely suited for applications involving thermally generated fume, especially when installed in a Donaldson Torit dust collector selected for your application.

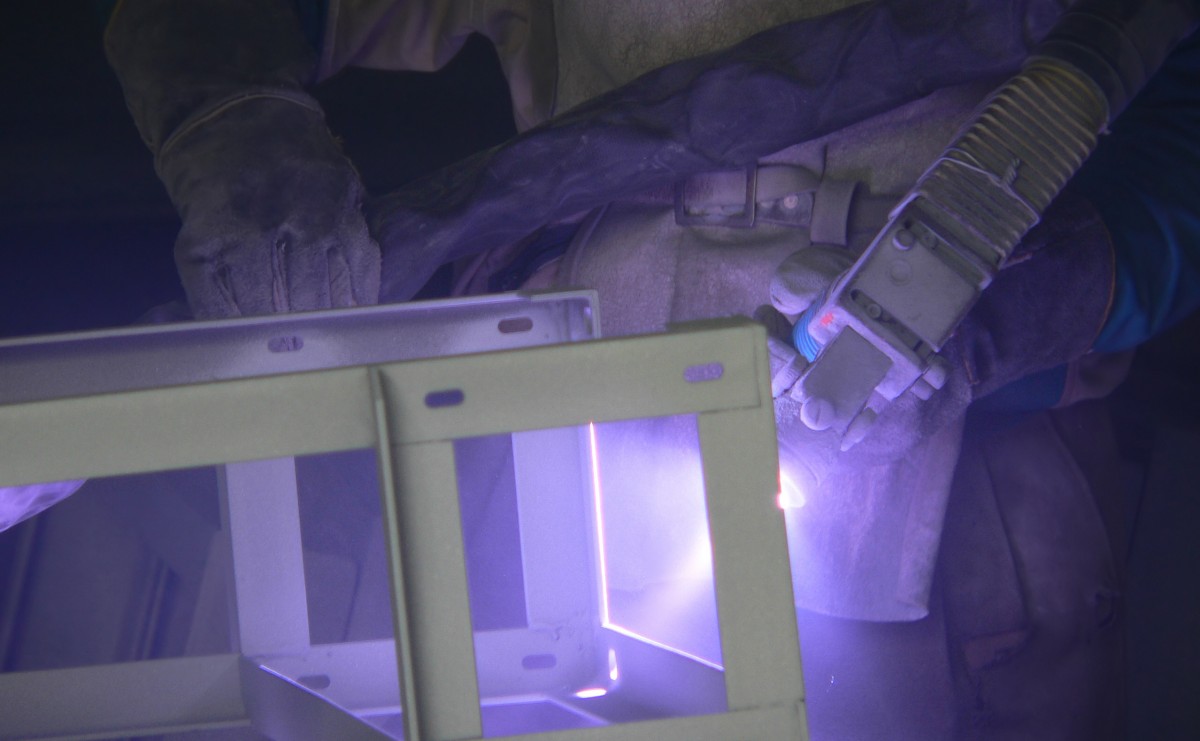

Thermal Spray or Metalizing is a group of coating processes which deposits finely divided metallic or non-metallic materials in a molten or semi-molten condition on a surface/substrate to form a coating. The coating material may start out in the form of a powder, ceramic rod, wires, or even molten materials. The process has the potential to generate very small particulate often referred to as “fume”. This thermally generated fume can be smaller than one micron in diameter, and uniform in size making collection a challenge.

Products

Applications

| Model | Product Family | Use | |

|---|---|---|---|

|

DFO 3-36 with 36 Cyclone Pre-Separator | Cartridge Dust Collector | Electric Arc Thermal Spray |

|

Downflo Oval (DFO) 4-16 | Cartridge Dust Collector | Metallizing |

|

(7) DFT 4-48 | Cartridge Dust Collector | Plasma Arc Spraying |

|

Downflo Oval (DFO) 3-18 | Cartridge Dust Collector | Powder Flame Spraying |

Articles