Overview

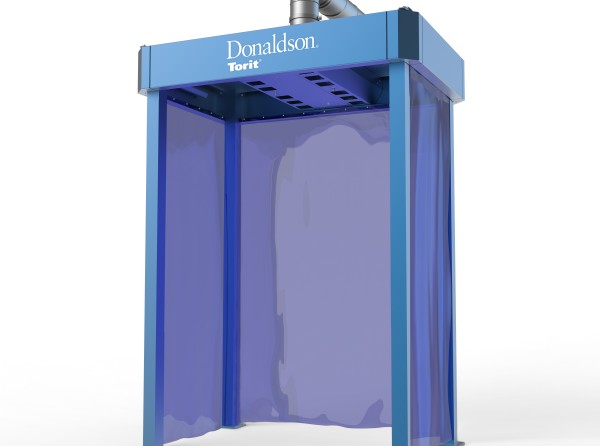

The versatile Donaldson Torit® WSO Mist Collector provides three filter solutions for water-soluble coolant, straight oil, and the most challenging, oily smoke. The WSO uses revolutionary Synteq™ XP Media Technology engineered for superior draining, resulting in lower pressure drop and longer filter life.

The WSO can be modified with a simple filter change, leading to leaner operation, cost savings and cleaner plant air.

Features

- 3 in 1 solutions for mist applications

- Advanced Synteq XP high efficiency media

- Cross-flow design for better drainage

- Easy to change cartridge filters

- Energy savings

- Continuous-duty design

- Lower life cycle costs

- Quiet operation

- Configurations for machine mounting, floor stands, or ducted central systems

- UL-approved electrical components

The WSO Difference

The WSO mist collector can be configured to meet your facility's requirements: machine mountable, floor-mounted stand, and ducted cellular and central systems.

Versatile in Application, Flexible in Design

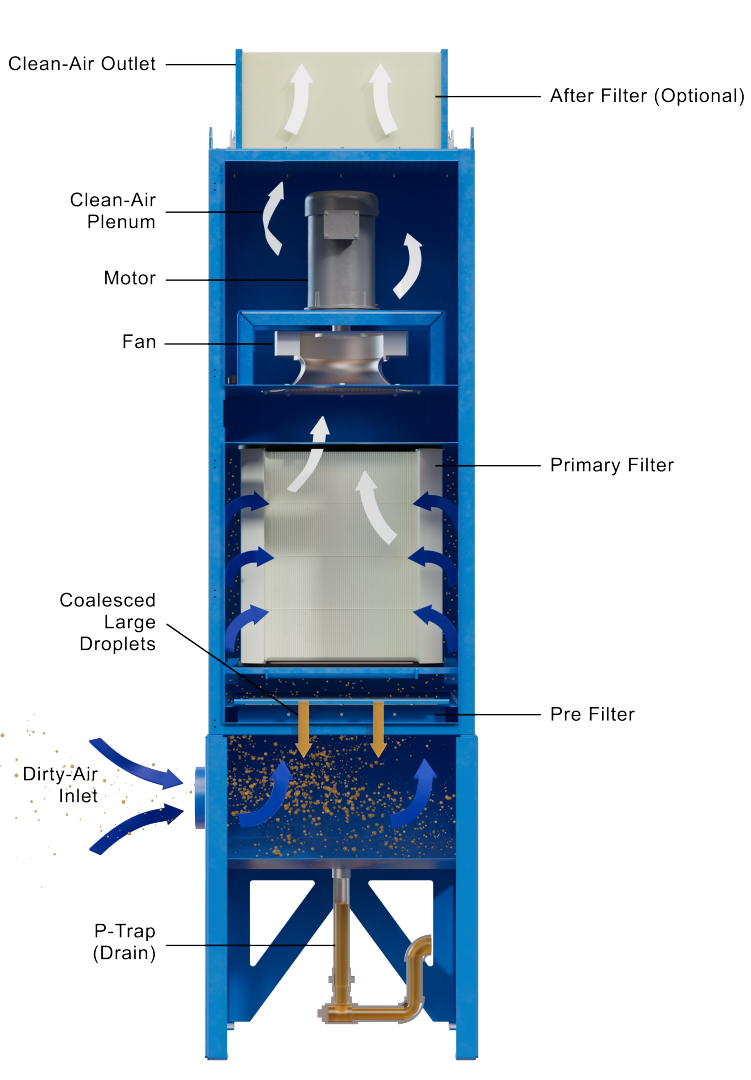

3rd Stage: Final Filter (Optional)

- DOP

- 95% efficient on .3 micron mist and smoke

- HEPA

- 99.97% efficient on .3 micron mist and smoke

2nd Stage: Primary Filter (Select One)

- Synteq XP - W

- For mist from water-soluble coolant

- Economical, fast draining, for heavy water-based liquid load

- Synteq XP - S

- For smoke from machining

- Highest efficiency for challenging applications

- Synteq XP - O

- For mist from straight oil machining

- Efficiency designed for small oil aerosols

1st Stage: Prefilter Options (Select One)

- Metal Screen

- For heavier dust/grit from wet grinding

- Metal Mesh

- For most water-soluble mist

- Polypropylene Mesh

- For most straight oil mist

- High Efficiency 1st Stage

- For oily smoke

Oblong Cartridges Outperform Traditional Filters

- Up to 45% more filter surface area than pocket filters and round cartridges

- Best fit in rectangular cabinet

- Lower pressure drop

- Longer filter life

Cross-Flow Design

Cross-flow filter design for better drainage means longer filter life. Dirty air flows horizontally through the walls of the WSO filter, perpendicular to drainage of collected and coalesced mist. This design promotes optimum drainage, which extends filter life and returns collected coolant for re-use.

Advanced Filter Media for Mist

Proprietary Synteq XP Media Technology is a revolutionary new media for mist collection that provides high efficiency, low operating pressure drop, and long filter life when compared to traditional media.

Synteq™ XP Media Technology with Resin-Frere Binding Fibers

- Engineered blend of small and large fibers, with proprietary, resin-free bonding system

- Small fibers are scientifically proven to increase efficiency

- Large fibers provide structural support and clear drain channels

- Proprietary bonding system stabilizes pore structure for optimum performance

Choose the Best Filter for Your Application

Water Soluble:

Typical Particle size: 2 - 20 micron

Smoke:

Typical Particle size: 0.07 - 1.2 micron

Oil:

Typical particle size: 0.8 - 5 micron

Accessories

Contact your Donaldson Sales Representative to order. Availability varies by country.

Resources

Service

1. Differential pressure gauge(s) identifies filter maintenance.

2. One pivot lever securely retains the primary filter element.

3. Filter is easily removed.

4. Simplified servicing means less maintenance time and cost.

FAQs

Q. What Are the Advantages of Synteq XP Media?

A. Proprietary Synteq XP Media is engineered with a blend of small and large fibers with a resin-free bonding system. The result is superior performance and longer filter life in the most challenging applications.

Q. What Size Are Mist Droplets/Particles?

A. Mist can generally be defined as a liquid droplet 20 microns in diameter or smaller. Oil-based fluids typically produce mist droplets that range from 0.5 microns to 10 microns. A smoke droplet is typically smaller, from 0.07 microns to 1 micron, and is a solid or liquid aerosol.

Q. What Determines the Performance of a Mist Collector?

A. A mist collector can be characterized by pressure drop, efficiency, and flow rate. Pressure drops affects the energy required to pull the airflow through the system. The efficiency of the system determines how clean the air will be as it leaves the collector and flow rate determines how much air will be cleaned.

Articles