Overview

Meeting Strict Emissions Regulations Are Within Reach When OEMs Incorporate Donaldson Emission-Control System Technology

Historically, the implementation of more stringent emission reduction regulations was led by Europe, North America, and Japan. However, many countries in other regions are now incorporating similar regulations, which is driving OEMs to include emissions reduction technology on more equipment models.

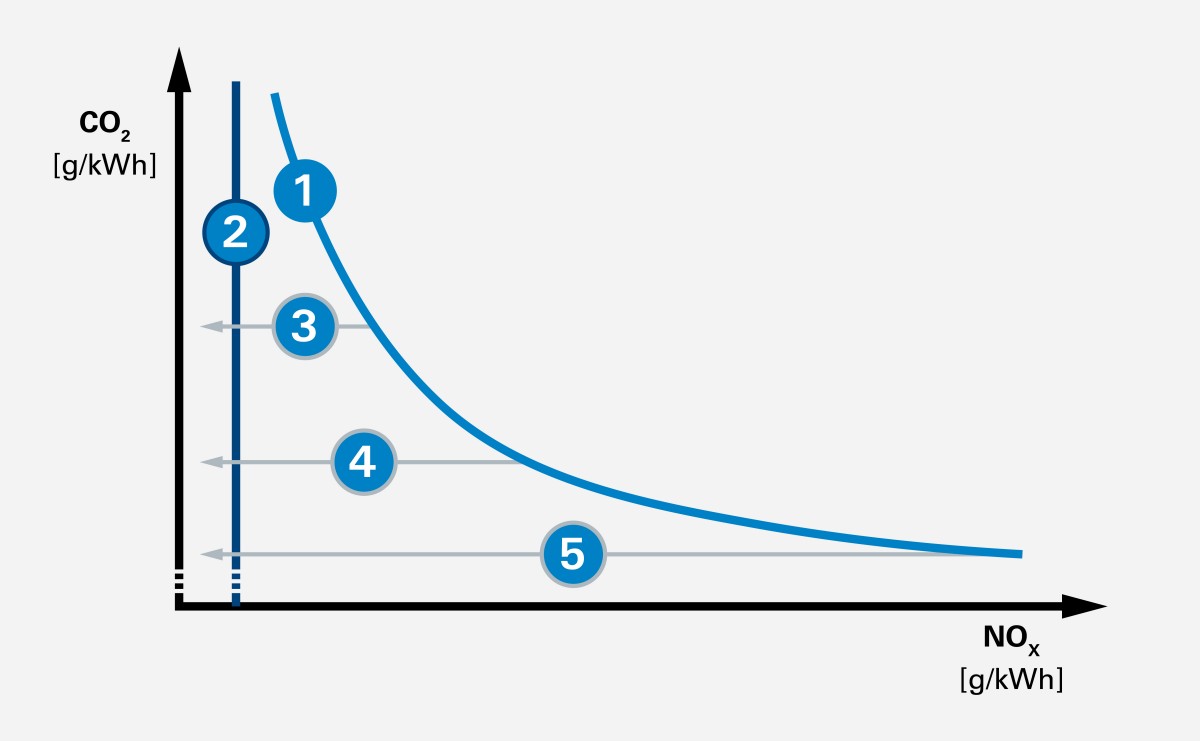

As with previous changes in emissions reduction, future technology is being driven by these stricter regulatory requirements. The trend is toward further reduction in oxides of nitrogen (NOx) while ensuring that particulate emissions stay low. Donaldson offers technology to meet or exceed these regulations, plus we’re beginning to focus on the reduction of carbon dioxide (CO2) emissions as well.

Features

Reduce Emissions and Boost Efficiency

Reducing emissions while improving engine efficiency is made easier with integrated emission control technologies from Donaldson. To meet strict emission reduction requirements, Donaldson provides OEMs with a range of integrated aftertreatment emission control technologies to effectively reduce NOx, CO2 and particulate emissions.

NOx Reduction

Increasingly stringent regulatory requirements in Europe and North America are driving toward further reduction in NOx emissions. The NOx thresholds for off-road applications will be reduced an additional order of magnitude compared to Tier 4 Final (U.S.) and Stage V (Europe) standards. To achieve these lower NOx requirements, several technologies (including those listed below) will need to be incorporated into aftertreatment systems.

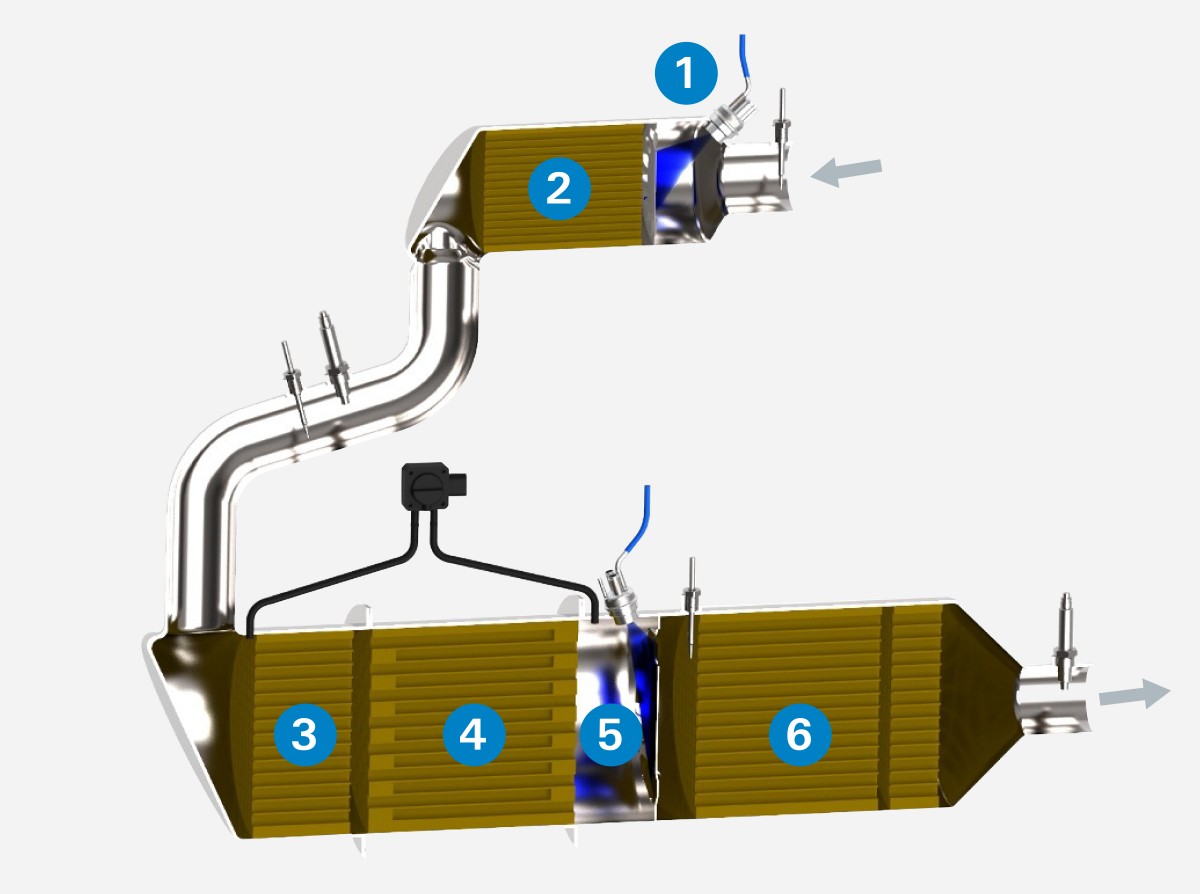

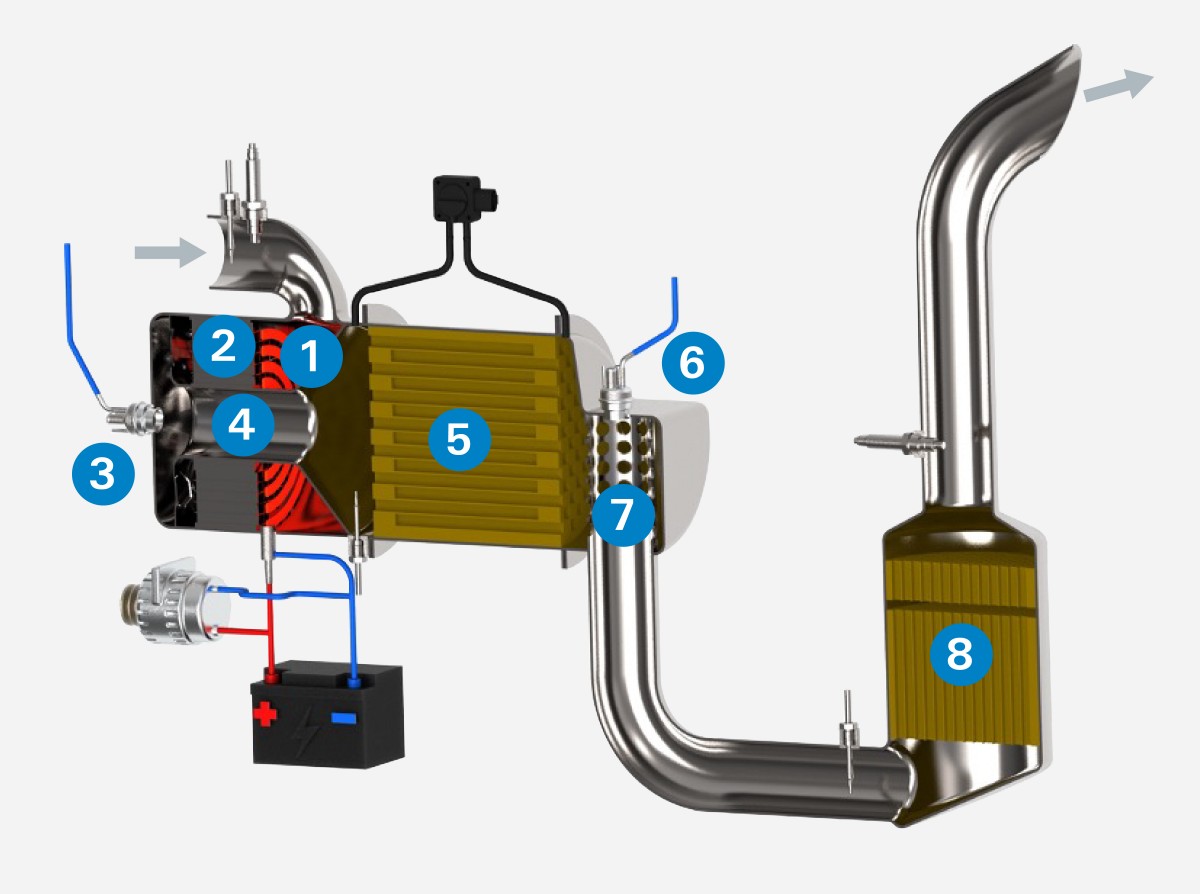

Close Coupling and Dual AdBlue® / Diesel Exhaust Fluid (DEF) Injection

Selective Catalytic Reduction (SCR) systems need heat in order to function properly. An additional (close-coupled) system located in close proximity to the engine can be incorporated to address start-up and overall NOx reduction requirements. Donaldson emission control system designs that incorporate the close-coupled and dual injection methods (AdBlue / DEF dosing) can be used to address technical requirements and the SCR’s need for heat to function properly.

Thermal Management

When operated at the correct temperature window, today’s aftertreatment systems achieve very high emissions reduction values. However, future emissions regulations are expected to focus on the areas outside of this temperature window. Therefore, it will be crucial to rapidly heat up aftertreatment systems, especially during a cold start. This can be achieved by minimizing the thermal inertia of all components and having a correctly insulated exhaust system to minimize heat loss. Additionally, it’s important that this heat stays within the system and that it’s not exposed to people and materials in the external environment (i.e., operators, technicians and environmental debris). To help OEMs address these challenges, Donaldson has a broad range of thermal management technologies available.

Additional Heating of Exhaust Flow

Additional heating of the exhaust can also be used to help to achieve NOx reduction standards during startup. Donaldson has decades of experience incorporating heaters into aftertreatment systems.

CO2 Reduction

Beyond NOx reduction, a well-designed aftertreatment system can allow an engine to perform more efficiently, thereby burning less fuel and generating less CO2. Close coupling and thermal management can also help an engine to operate at its most fuel-efficient level.

By using improved thermal management to reduce the amount of engine energy needed to heat an aftertreatment system, greater efficiency can be created by redirecting that unused energy into equipment work. By minimizing backpressure, we allow the engine to operate at high-efficiency levels, thereby minimizing CO2 output. Additionally, reducing the size and weight of aftertreatment systems – through good design practices and system integration – can contribute to reduced fuel consumption and reduced CO2 emissions.

Particulate Reduction

The current emissions legislation for particulates focuses on Particulate Mass (U.S.) and Particulate Numbers (Europe). Future emissions legislation is expected to be stricter on particulates. Donaldson diesel particulate filters (DPFs) are a well-known and established technology to meet these tailpipe particulate emission levels.

Articles

Resources