Overview

Your passengers and crew expect a comfortable flight experience, and that includes clean, quality air for breathing. Recirculated and pressurized air can contain gaseous elements and airborne particulates, resulting in poor cabin air quality. To help remove these elements and help purify the air, look to Donaldson for the latest technologies in fixed-wing cabin air filtration.

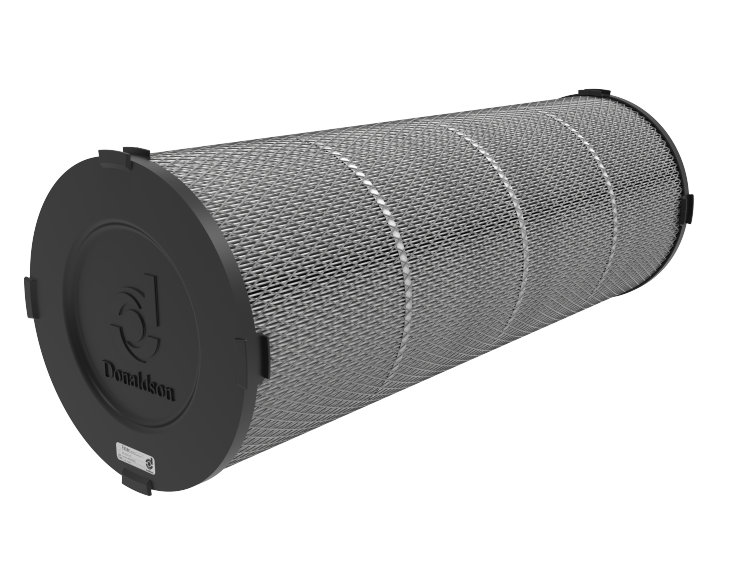

HEPA Filters

HEPA filters (high efficiency particulate air) provide a superior level of cabin air filtration to meet industry efficiency standards. Donaldson designs and manufacturers HEPA air filters in a variety of shapes and sizes depending on your application needs.

We offer custom designed OEM filters and a wide range of PMA approved aftermarket filters to fit a variety of aircraft platforms.

Donaldson offers HEPA filtration solutions for the top commercial aircraft brands including Airbus, Boeing, Bombardier, and Embraer. We continuously work to expand our HEPA filter range to meet the growing needs of the industry.

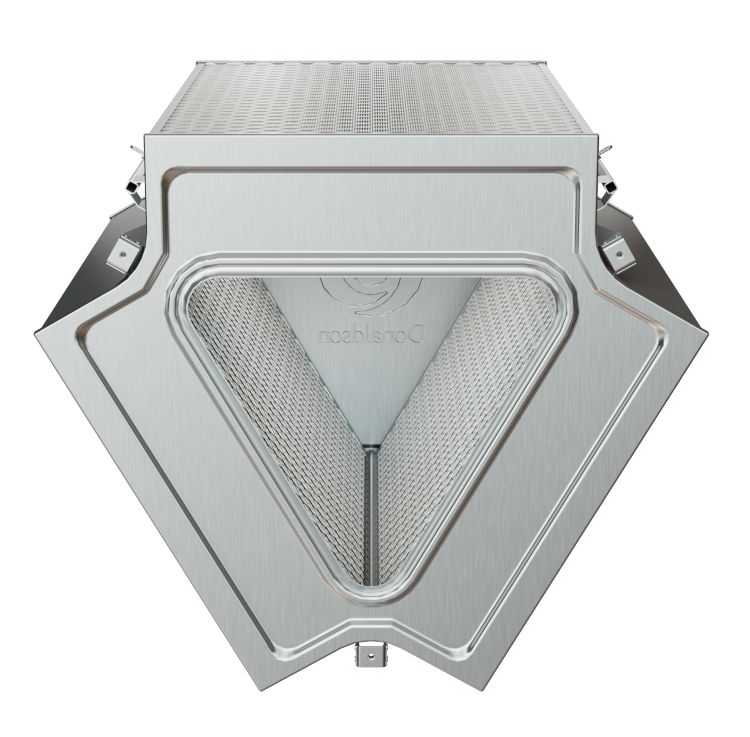

Air Purification Systems

Donaldson Air Purification Systems (APS) technology delivers a two-stage filtration process in a single filter, combining both chemical and particulate filtration into one. The chemical filtration relies on a technical process called gas phase adsorption. The gas phase adsorption process removes bio-effluents, fuel by-products, cleaning agents, emissions from internal materials, cosmetics, and other personal care products. The HEPA particulate stage removes the dust, allergens, and other irritating particles from the air.

These two stages work together as a filtration system to remove dust, allergens, and other irritating particles from the air in pressurized cabins and cockpits.

Resources