Overview

Rotorcraft and general aviation aircraft routinely contend with dust, sand and debris that can attack engines, affecting their performance and reliability. You can help prevent damage, from efficiency loss to engine failure, by installing high-quality aircraft engine air filters.

At Donaldson, we specialize in developing top-of-the-line solutions to help protect your aircraft engine inlets. Our products, such as inlet barrier filters (IBF) and engine air particle separators (EAPS), are designed to keep your engines running smoothly with minimal maintenance. That’s why we are recognized as a leader in supplying reliable and easy-to-use engine air inlet filters.

Rotorcraft

Helicopters operate in diverse conditions, from fires and dust storms to deserts, snow, and high-salt environments. Contaminants entering turbine air inlets is inevitable, in addition to the dust cloud rotorcraft churn up every time they take off and land.

IBFs are capable of separating contamination from the airflow prior to reaching the turbine. Donaldson Inlet Barrier Filters offer advanced protection for both OEM-integrated and aftermarket rotorcraft applications. Our IBF filters are designed to meet customer expectations and help increase efficiency, protect engines and reduce costs.

Whether you need OE-integrated or aftermarket-retrofitted IBF system, we offer advanced protection for your rotorcraft air inlets.

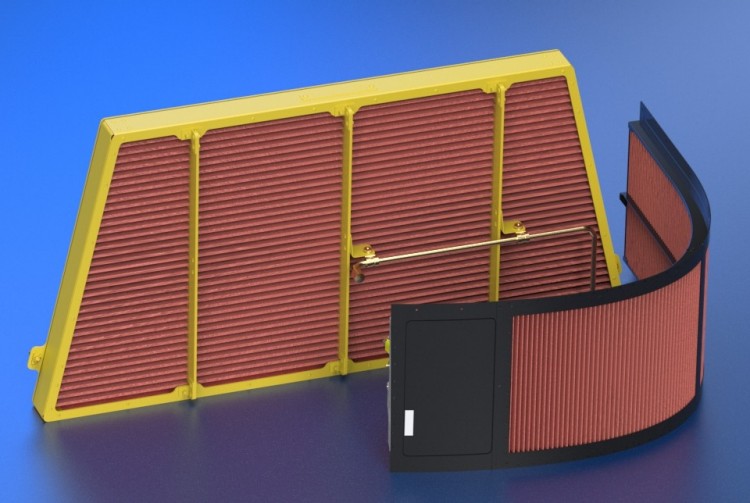

IBF Systems

We offer custom systems to suit your exact needs, whether you’re considering an IBF as an OEM-supplied option or for a retrofit application.

Additionally, they capture contaminants and FOD (foreign object debris) to help prevent engine damage and the risk of catastrophic failure.

IBF systems help shield sensitive and expensive components and systems:

- Compressors

- Combustors

- Turbines

- Pneumatic systems

- APU

- Piping

- Valves

- Air turbine starters

- and more

IBF Oiled and Dry Filters

Choose from oiled or dry media options that fit your performance requirements and preferred maintenance practices.

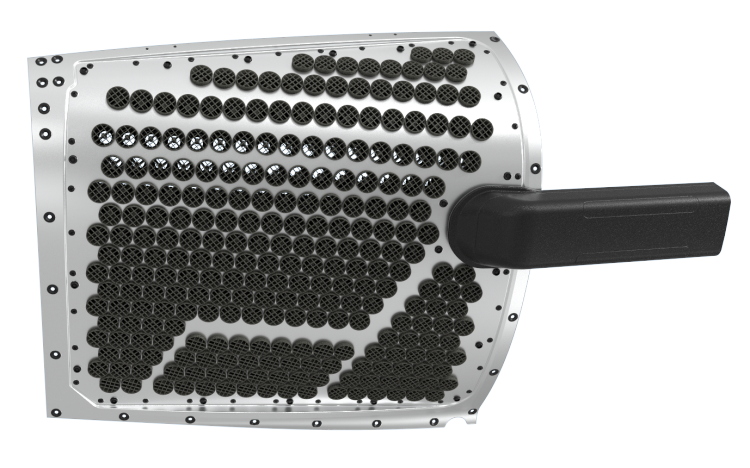

Engine Air Particle Protection System (EAPPS)

As pioneers of the engine air particle separator (EAPPS) system, Donaldson offers a range of highly efficient helicopter inlet particle separators for all types of applications and specific equipment needs.

High-efficiency EAPPS systems remove particulate types from air flows while still providing low airflow restriction.

Our particle separators are self-cleaning and have no moving parts to wear out or break — helping to reduce the need for regular maintenance.

General Aviation

GA aircraft often operate from smaller, less maintained airstrips, where exposure to dust, sand, and dirt is unavoidable. Donaldson engine intake filtration systems for general aircraft are engineered to help protect engines from airborne contaminants from damage.

Designed to manufacturer specifications, our filters are easy to install and maintain, because with no removable parts or oil, they can be washed with water to help achieve life performance expectations.

Resources