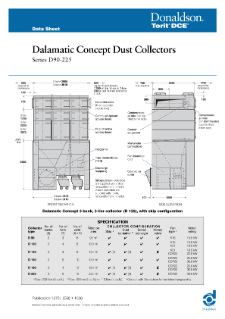

Overview

The Dalamatic® series of dust collectors (Cased and Insertable) are unique in that they both come standard with envelope shaped bags and cages, but that is where the similarities end.

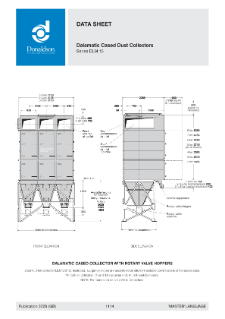

The Cased Dalamatic (DLMC) is a stand alone collector with support legs and hopper. The inlet is at the top of the collector to drive dusty air down towards the hopper. This downward air pattern helps to keep dust pulsed off of the bags moving towards the hopper and therefore reduces dust re-entrainment on the bags. This makes the DLMC a popular choice for light and fluffy dust applications.

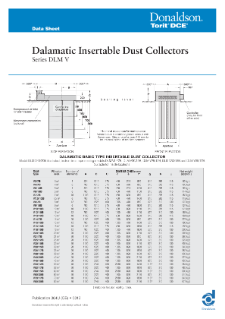

In contrast, the Dalamatic Insertable (DLMV) has no legs and hopper. The DLMV is used in applications such as bin venting where the collector is mounted on top of a bin or silo and the bags are often times actually inserted inside the top of the bin. As the bin or silo is being filled, dusty air is filtered by the DLMV with cleaned air exiting the collector. Once a dust cake forms on the outside of the bags, a pulse of compressed air inflates the bag and breaks the dust cake free of the bag depositing the material back into the bin or silo so no material is wasted.

Continuous Dust Collection

Provides continuous filtration of high dust concentrations at high filtration velocities and constant levels of resistance in almost any industry and application.

Compact Design

Unique modular design allows for installation in the most space restricted areas. Envelope-shaped bags maximize the amount of media in a given space and allow for increased space between bags, minimizing the chances of bridging.

Dura-Life™ Bag Filters

Provide better surface loading and better pulse cleaning reducing maintenance and operating costs.

Helix Tube Filters

Optional Helix Tube Filters with laminated ePTFE membrane provide higher filtration efficiency resulting in lower emissions. Filters take up to 25% less time to replace thus reducing maintenance costs.

Versatility

A full range of sizes and types of bags are available for a wide variety of dust collection applications.

Unique Bag Design

The Dalamatic advantage is found in the breakthrough technology of Dura-Life bag filters in an envelope shape. The envelope shape provides greater movement of the bag to dislodge more challenging dust cakes during filter pulsing.

- Dust accumulates on the outer surface of the filter bag as air penetrates the media

- The blowpipe (jet tube) injects a burst of compressed air into the bag filter

- Airflow is then briefly reversed, inflating the bag filter and dislodging dust

- The dislodged dust cake falls into the collection hopper for final removal or directly back in the process. The envelope-shaped bag filter, which is mounted on a unique wire frame, ensures optimum airflow and thorough cleaning.

Accessories

Contact your Donaldson Sales Representative to order. Availability varies by country.

Resources

FAQs

Q. What Is a Hydro-Entanglement Process?

A. Instead of a mechanical process using needles to entangle and compress polyester fibers into a felt material, the hydro-entanglement process uses jets of water to entangle and compress the polyester fibers into felt. The process creates a material that is more uniform and provides better filtration.

Q. How Are Dura-Life Bags Different from Standard Polyester Bags?

A. Dura-Life bags are made from polyester material that is created through a hydro-entanglement process instead of a needle punch process. The hydro-entanglement process creates a more consistent and uniform filter material. The material is comparable in thickness to standard polyester, but weighs about 1/3 less. The fibers are smaller and the hydro-entanglement process creates a loftier and lighter weight fabric that filters more effectively.

Videos

Articles