Overview

The MB provides reliable service with easy maintenance. Computer designed inlets and deflector plates, coupled with maximized bag spacing, result in optimal airflow with minimal abrasion. Advanced valves, providing 50% more cleaning air, result in a more efficient operation. Over the life of the collector, no other baghouse can provide this much value.

The MB advantage is found in the breakthrough technology of our filter bags. Dura-Life™ filter bags and Ultra-Web® pleated bag filters. Dura-Life filter bags provide twice the life over standard 540 g/m² / 16 oz/yd² polyester bags. Our pleated bag options with Ultra-Web SB, provide longer filter life and reduced emissions. Both options can lower the overall cost of operation of the collector.

- High body inlet models allow higher air-to-media ratios on lighter dusts

- Square models help minimize ducting and accessory costs

- Dura-Life ”Twice the Life” Bag Filters

- Ultra-Web SB Pleated Bag option

- Clean air bag access for easier bag service

- Welded design increases durability

- Integral fan option reduces space requirements

- Quick-Release Filter Bag Cages allow for tool-free installation of bag filters and cages

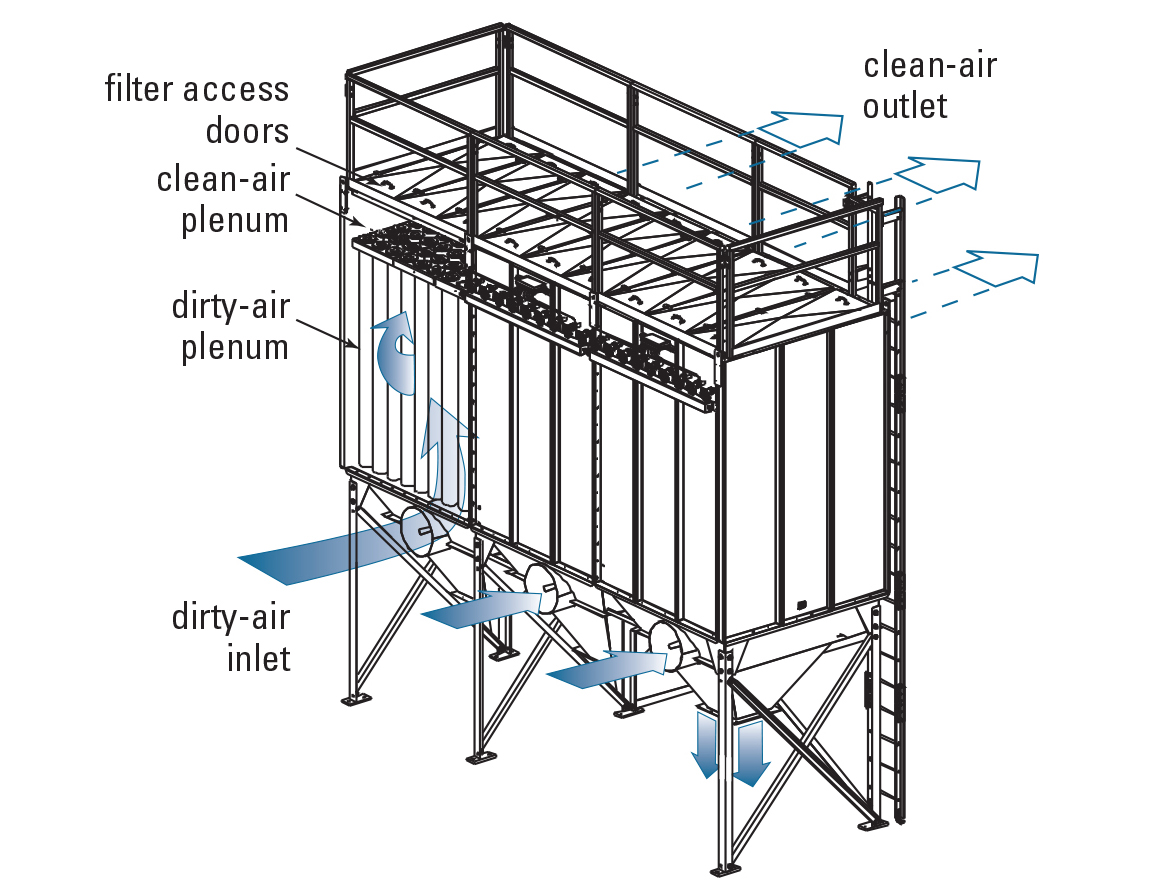

Baghouse Operations That Work

The MBT model allows walk-on, top access to the bags (clean-air side) of the collector. This configuration is ideal for indoor or tight budget applications.

The MB has two inlet configurations; the most common configuration allows the dirty-air to enter through the hopper inlet located under the bag filters. The dirty air hits a deflector at the end of the inlet, which causes heavy particulate to fall directly into the hopper. This reduces the amount of dust that comes in contact with the bags resulting in longer bag life and lower pressure drop. For applications with light and fibrous dust, a high body inlet is available that reduces upward air velocities allowing the dust to properly fall into the hopper after the bags have been pulsed.

Baghouse Operations That Work

The Modular Baghouse collector comes in two models: the MBT allows walk-on, top access to the bags (clean-air side) of the collector. This configuration is ideal for indoor or tight budget applications. The MBW offers a walk-in clean-air plenum, so bags can be replaced in any kind of outdoor weather.

The Modular Baghouse has a hopper inlet that was designed with the help of computer airflow analysis to provide maximum performance. When dusty air enters the inlet, it hits a deflector plate at the end of the inlet, which causes heavier particles to drop directly into the hopper. This design reduces the amount of dust that comes in contact with the bags, thus reducing bag abrasion and providing reduced pressure drop and longer bag life.

Dumpster Discharge for Heavy Dust Loading

For applications with heavy dust loading, the MB has an easy to use Dumpster Discharge. This option provides either a 1.5 or 2.3 cubic meter / two or three cubic yard self-dumping dumpster that can be hauled away with the use of a forklift. The dumpster comes with a lid that seals the system so that no rotary valve is required. The lid is lifted off of the dumpster via a mechanical lift, which is included with the package.

Two Breakthrough Filter Options for Your Modular Baghouse

Dura-Life Filter Bags Provide Twice the Life Over Standard 540 g/m2 / 16 oz/yd2 Polyester Bags

Traditional 540 g/m2 / 16 oz/yd2 polyester bags are produced via a needling process that creates larger pores where dust can embed into the fabric, inhibiting cleaning and reducing bag life. Dura-Life bags are engineered with a unique hydroentanglement process that uses water jets to blend the fibers. This process creates a felt with smaller pores which keeps more dust on the surface of the filter resulting in better pulse cleaning and longer bags life.

Dura-Life Filter Bag Benefits:

- Up to two times longer bag life

- Energy savings due to lower pressure drop

- Reduced replacement bag and maintenance costs due to longer bag life

Pleated Bags with Ultra-Web SB Provide Longer Life and Reduced Emissions

For more than two decades, Donaldson Torit has advanced the proven Ultra-Web fine fiber technology. Ultra-Web provides a very fine, continuous fiber of 0.2 - 0.3 micron in diameter to form a web-like net that traps dust on the surface of the media. Combining Ultra-Web technology with a sturdy spunbond polyester substrate, Ultra-Web SB pleated bag filters provide longer life, reduced downtime and reduced emissions.

Ultra-Web SB Pleated Bag Benefits:

- Reduced collector size and first cost

- Up to two times longer filter life

- Energy savings due to lower pressure drop

- Reduced maintenance and downtime costs

- Reduced emissions

Features

| Collector Design | Standard | Optional |

|---|---|---|

| Clean Air Plenum with Top-Bag Removal | ||

| Top Access Lift Doors | ||

| All-Welded, Carbon Steel Design | ||

| Integrated Filter Cleaning System | ||

| Service Platform and Access Ladder | ||

| High Temperature Construction +200° C | ||

| Temperatures 10° C to +60° C | ||

| Operating Pressure - 500mm H2O |

| Bags & Cages | Standard | Optional |

|---|---|---|

| Dura-Life Polyester Bags | ||

| Single Piece Cage with Internal Venturi | ||

| Mid Steel Galvanized Quick-Release Bag Cages | ||

| Mid Steel Powder Coating Quick-Release Bag Cages | ||

| Variety of Bag Media Options (Oleophobic, Antistatic, Oleophobic Antistatic, Nomex) | ||

| Sealing Arrangement - Stainless Steel Snap Ring and Double Cuff |

| Hopper Design | Standard | Optional |

|---|---|---|

| Pyramid Hoppers | ||

| Inlets and Deflector Arrangement | ||

| Trough/Valley Hopper | ||

| Hopper Access Covers |

| Hopper Discharge | Standard | Optional |

|---|---|---|

| Pyramid Hopper Flange to Accept Rotary Valve | ||

| Valley Hopper Flange to Accept Screw Conveyor |

| Support Structure | Standard | Optional |

|---|---|---|

| Clearance Leg Pack |

| Electrical Controls, Gauges and Enclosures | Standard | Optional |

|---|---|---|

| IPC | ||

| TCB/IPC DP |

| Safety Features | Standard | Optional |

|---|---|---|

| Explosion Vents | ||

| ATEX Compliant |

| Special Options | Standard | Optional |

|---|---|---|

| Dirty Side Stainless Steel | ||

| Stainless Steel Construction | ||

| Operating Pressure - 1000mm H2O | ||

| Cell Isolation | ||

| Sprinkler System | ||

| Insulation and Heating | ||

| Explosion Suppression | ||

| High Temperature Construction +250° C |

| Paint System | Standard | Optional |

|---|---|---|

| Standard Water Based Paint Finish |

Accessories

Contact your Donaldson Sales Representative to order. Availability varies by country.

Resources

FAQs

Q. What Is a Hydro-Entanglement Process?

A. Instead of a mechanical process using needles to entangle and compress polyester fibers into a felt material, the hydro-entanglement process uses jets of water to entable and compree the polyester fibers into felt. The process creates a material that is more uniform and provides better filtration.

Q. How Are Dura-Life Bags Different from Standard Polyester Bags?

A. Dura-Life bags are made from polyester material that is created through a hydro-entanglement process instead of a needle punch process. The hydro-entanglement process creates a more consistent and uniform filter material. The material is comparable in thickness to standard polyester, but weighs about 1/3 less. The fibers are smaller and the hydro-entanglement process creates a loftier and lighter weight fabric that filters more effectively.

Videos

Dura-Life Bag Filters

Pleated Bag Filter Installation and Removal

Snap Band Bag Filter Installation

Articles