Overview

The breakthrough performance of the Downflo® Evolution (DFE) family of cartridge dust collectors is the result of Donaldson Torit’s relentless drive to improve its products and exceed customer expectations. Donaldson Torit put decades of industry experience to work to produce a new, best-in-class dust collector capable of reducing equipment size and number of required filters by up to 40% compared to a typical cartridge collector.

A smaller collector helps lower the initial purchase price, reduces filter replacement costs, and opens up valuable manufacturing floor space.

This state of the art collector, coupled with Donaldson’s industry-leading Ultra-Web® fine fiber filtration technology, delivers a significantly smaller equipment footprint with up to 40% fewer filters required, reducing maintenance time and overall cost of operation.

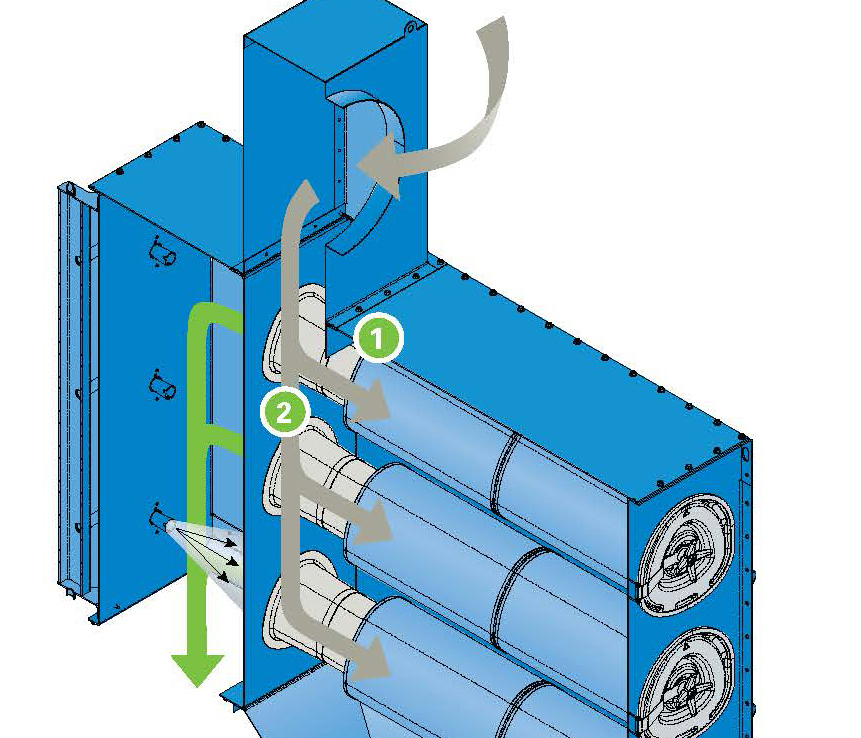

- Revolutionary Airflow Management

Directs incoming air to an intelligent dropout zone for reduced filter loading

- Breakthrough Filter Cleaning

MaxPulse™ Cleaning System delivers 27% more cleaning energy to filtration media

- Industry-Leading Filtration Design

Positions more filtration media in beneficial locations and ensures easy, leak-free installation with Ultra-Web media as standard

Revolutionary Airflow Management

The DFE’s game-changing dust collection performance is achieved through a combination of design features that result in significant customer benefits.

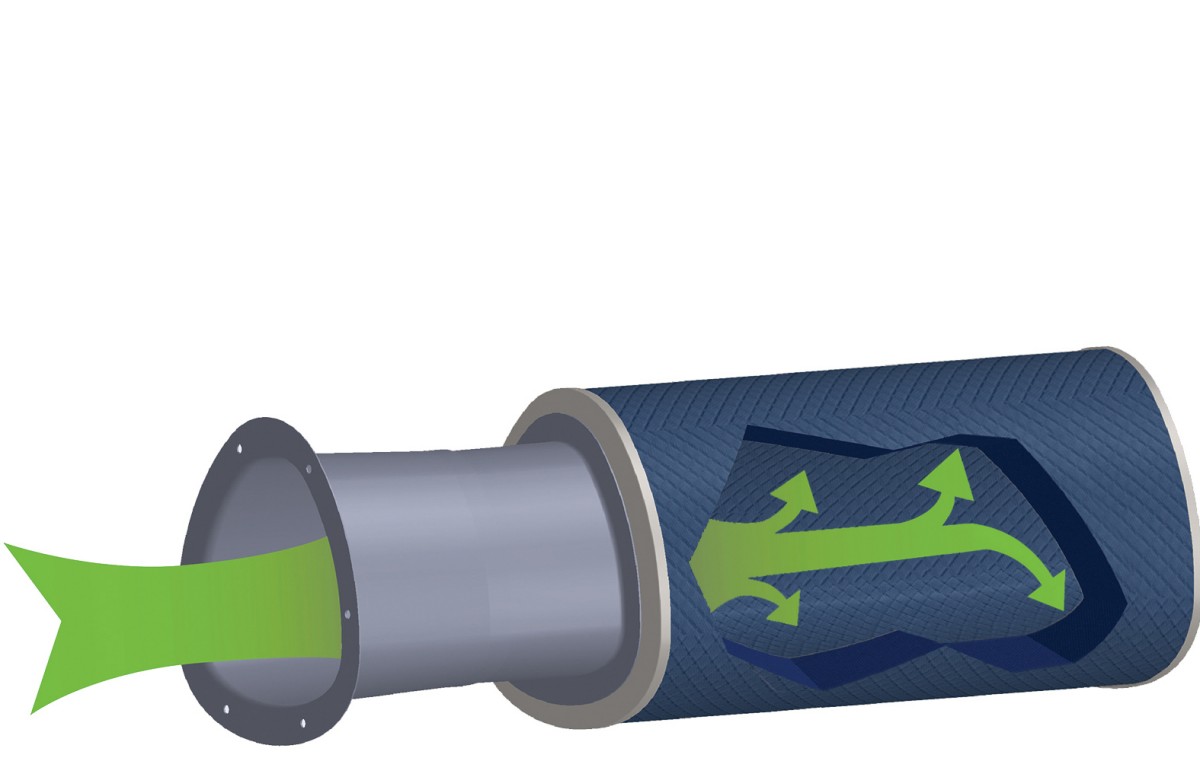

Breakthrough Filter Cleaning

The DFE provides breakthrough cleaning performance resulting in improved filtration capacity without sacrificing filter life or taxing compressed air consumption.

The MaxPulse™ Cleaning System delivers 27% more cleaning energy to filtration media. This minimizes energy losses by focusing on the cleaning air’s exact path and delivers uniform cleaning energy to all effective filtration media.

Our proprietary, pulse-shaping design distributes the cleaning energy evenly to match the unique shape of the filter.

More effective cleaning of the filtration media results in increased airflow capacities through Donaldson Torit dust collection equipment.

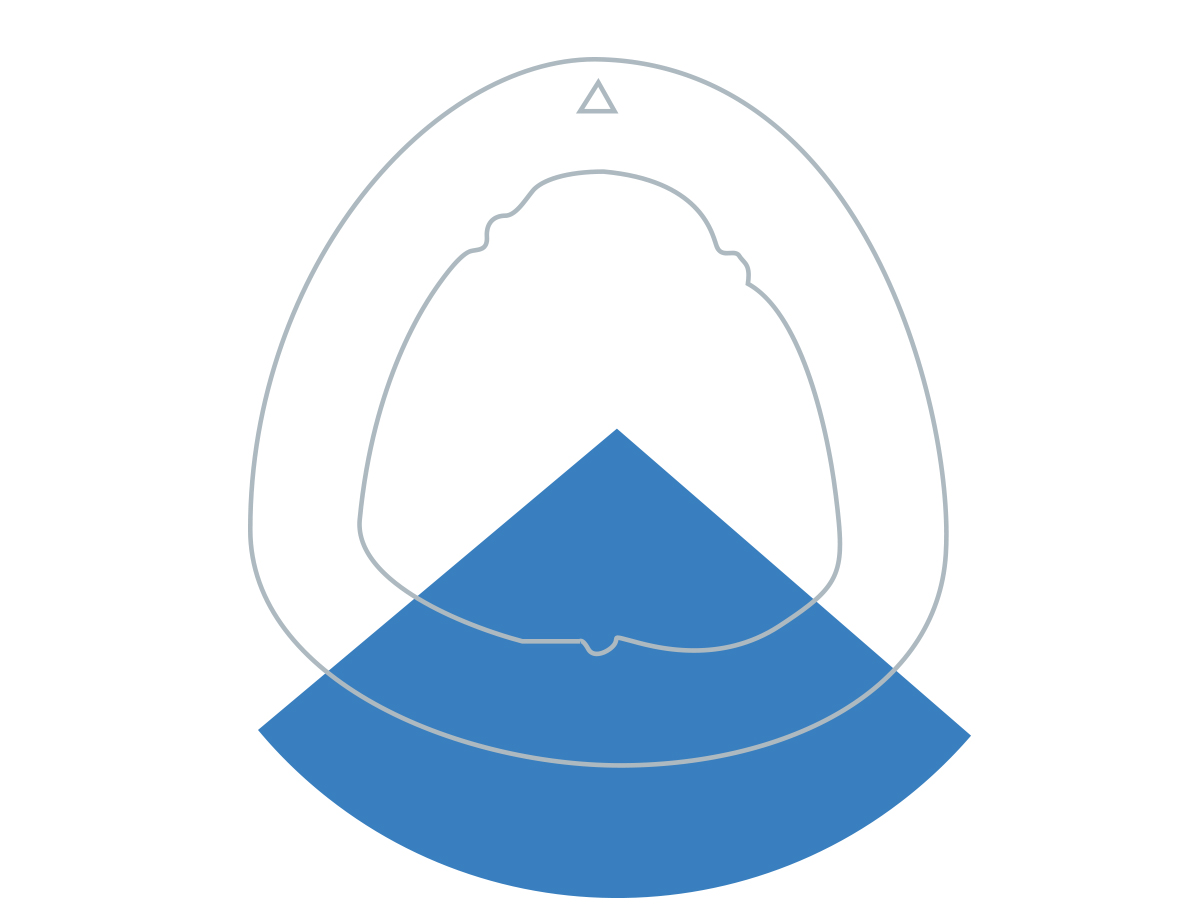

Industry-Leading Filtration Design

The DFE filter design is another indication of Donaldson Torit’s commitment to technical research and development.

The DFE’s unique shape positions more filter media at the bottom of the cartridge element so pulse-cleaning energy directs the ejected dust toward its ultimate destination – the containment vessel.

25% Round

27% Triagonal Filter

Quick Filter Changeout

The interior of the metal filter element endcaps features a specific profile that engages with the collection equipment’s support yoke.

No special tools are required, and you never have to enter a confined space or dirty air plenum to do the job.

Features

| Collector Design | Standard | Optional |

|---|---|---|

| Mild Steel Construction | ||

| MaxPulse™ Filter Cleaning System | ||

| Quick-Removal Access Covers | ||

| Inlets | ||

| Ledge-Free Hopper | ||

| Sprinkler Taps | ||

| Stainless Steel Construction | ||

| High Temperature Construction | ||

| Explosion Protected Models | ||

| Direct Drive Fans | ||

| Chamber and Exhaust Silencers | ||

| High-Flow Inlet | ||

| Air Management Modules | ||

| Extended Dirty Air Plenum | ||

| Sprinkler Heads | ||

| Service Platform (OSHA compliant) | ||

| Lined Clean Air Plenum | ||

| Bag-Out Kit (Filter & Discharge) |

| Cartridge Filters | Standard | Optional |

|---|---|---|

| Ultra-Web® (MERV* 15) | ||

| Ultra-Web® FR (MERV* 15); Ultra-Web® SB (MERV* 15); Ultra-Web® AS (MERV* 15); Fibra-Web® (MERV* 14); Thermo-Web™ (MERV* 14); Torit-Tex™ (MERV* 16); High Temp (MERV 13) |

||

| HEPA/ASHRAE Afterfilters |

| Paint System | Standard | Optional |

|---|---|---|

| ISO 12944-5 C3 | ||

| ISO 12944-5 C3, C4, C5 | ||

| Custom Color |

| Hopper Discharge | Standard | Optional |

|---|---|---|

| Hook-On Dustbin | ||

| Butterfly + Dustbin Kit 200L Pred=0, 4bar -1500 | ||

| 200L / 52.8 gal Drum | ||

| Rotary Airlock H-AX250 | ||

| Bin Balance Kit | ||

| Butterfly Valve w/ Reinforced 85 l Dustbin Pred=0,75 - 1065 | ||

| Slide Gates | ||

| Rotary Valves and Transitions | ||

| Screw Conveyors | ||

| Sealed Drum Kit (SDK) | |

| Electrical Controls, Gauges & Enclosures | Standard | Optional |

|---|---|---|

| C100 Controller + Valvebox | ||

| C200 Controller + Valvebox | ||

| C300 Controller + Valvebox | ||

| Atex Rated Controls | ||

| Magnehelic®** Gauge | ||

| Custom Panels |

Accessories

Contact your Donaldson Sales Representative to order. Availability varies by country.

Resources

Videos

Ultra-Web Technology Provides Filters that Deliver

Downflo Evolution Dust Collector

Donaldson Torit introduces a new family of dust collectors called Downflo Evolution. This state of the art collector, coupled with Donaldson’s industry-leading Ultra-Web fine fiber filtration technology, delivers a significantly smaller equipment footprint with up to 40% fewer filters required, reducing maintenance time and overall cost of operation.

Articles